has any one had any expereance with there product's? i'm wanting to put a small combination lathe, milling machine in my work shop, any info on this will be appreciated. thank's

skimmerhead

|

|

|

has any one had any expereance with there product's? i'm wanting to put a small combination lathe, milling machine in my work shop, any info on this will be appreciated. thank's

skimmerhead

Cheap things are not good and Good Thing's Are Not Cheap

the worst part of getting old; is remembering when you were young

I have never owned or used one but looking at them they leave a lot to be desired. In reading posts on machining forums some people love them, others feel that they are better than nothing and others think they are utterly useless being neither a good mill or a good lathe.

One of the intents of the design is to save space but at the cost of taking up large amounts of time reconfiguring the machine from lathe mode to mill mode. The rigidity of both leave a lot to be desired and to achieve close tolerances and a good finish that is a necessary component.

The same machines can be bought from Harbor Freight.

Your question is answered in your signature"Cheap things are not good and Good Things Are Not Cheap".

Try reading some posts on "The Home Shop Machinist " forum.

My opinion, FWIW, is not to get a combo. I have used a combo before and it was a pain to use. A separate lathe & mill works better. The cost of the basic machine is not the big expense as the additional tooling you need will cost more. For example: my collet set, cutting & boring tools, knurling tool set, tool post, cost way more than my lathe. Same with the milling machine.

Bliksem

doesen't sound like what i want, any suggestions? don't want a big machine 24-36 inch centers somewhere in that range. nothing for production, just hobby. thank's don't know where to find home machine shop forum.

skimmerhead

Last edited by skimmerhead; 07-05-2010 at 03:00 PM.

Cheap things are not good and Good Thing's Are Not Cheap

the worst part of getting old; is remembering when you were young

thank you sir! i will start doeing research before buying a machine, i realize my signature is up for interpetaion so i may add to it, my interpation= freedom, and all the people who have paid the ultimate price for us to enjoy the liberty's that our constitution is meant to provide. myself have not served in the military being 4-f with a bad back, but went to new orleans to join the marines, but didn't pass phisical. i wanted to go to nam bad as a lot of my friends went and many did not return. but i'm proud to say my son spent 9 years in the army. retired an e-4 crew chief on a black hawk, and served in desert storm. wow i really got away from the subject here, sorry to ramble on.

skimmerhead

Cheap things are not good and Good Thing's Are Not Cheap

the worst part of getting old; is remembering when you were young

i was thinking of getting one myself, and was talking to a few machinist friends of mine,some said depends how much you will use it.others said they were junk, just depends on who you ask. but i think if you don't use it whole lot and take care of it will last a while, but verus the price of buying seperate machines, which could run up to thousands of dollars. and just for a hobby. it would be different if you was going to make a living with them. i'm a machanic by trade and it took me a long time to find out that it's hard make a living with cheap tools, while it can be done. but it is very frustrating. but if it's at home for personal use you can use what ever kind of tools you want to. lol

you rite bout that izzy, if it's to have a tool that you can;t do what you want with it then whats the point, don't send a kid to do a mans job.

skimmerhead

Cheap things are not good and Good Thing's Are Not Cheap

the worst part of getting old; is remembering when you were young

my uncle has one thought the world of it. then one day he comes in my shop talking about the lathe he bought so he would not have to tear down the mill. then a little later he comes in talking about the mill he bought now he does not have to teardown the lathe.

so there it is bought the right machines after he got the wrong one.

This forum is as good as any for this topic.

I can recommend the Birmingham 12x36" lathe without reservations. I bought mine in March 2005. I've been a home machinist since 1979, have a year of tool-machine engineering at the college level so this isn't new to me. I've used all manner of common lathes from Atlas 10" to Clausing 6300, South Bend, LeBlond and my old 1903 Von Wyck 15x60. I paid $2,000 + $300 freight from Henderson, Nevada to northern Indiana. I think they're a little more now.

I made my own 5C handwheel collet closer. The 3 jaw that comes with it is ok and the 4 jaw is better than ok. The lathe is very capable of sub-.001" tolerance if needed. There are weak points. The lowest speed could be a little slower for threading up to a shoulder. There are a couple ways to deal with that, one of which is a smaller motor pulley. Speed selection is fine. Hole through spindle is 1.5" which is very nice to have. I would council against a bed shorter than 36".

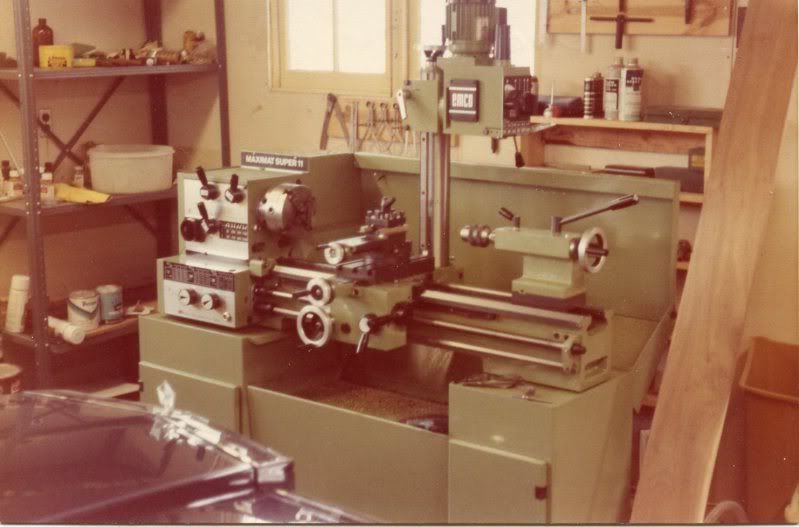

A milling machine is a bit tougher decision. The one in the above photo is an Index Model 40 built in 1942 and used by Douglas Aircraft during WW2 for navy aircraft. I bought it in 1981 for $1,300 from a used machinery dealer in Los Angeles. I've used it 28 years so it must be ok. But it was archaic. So in March 2009 I bought a used Enco 1525 8x36" "baby bridgeport" for $1,700 and had it shipped from Madison, Wisconsin to northern Calif. Got it from another gun collector that I knew so I trusted what he was telling me about it plus he's a machinist by trade.

I have hardly stopped using it since I got it cleaned up and running. It weighs 1,700 pounds to the 1,200 of the Index. No complaints about it. Since it has a 3 phase motor I opted for a rotary converter for about $340 off fleaby. American Rotary. No complaints. Lots of power with a 1.5 hp 3 ph motor. 10 speeds from 100 rpm to 3200 and 3200 is really singing. Fast enough to do some minor precision grinding. This machine has paid for itself 2x now in 1 1/2 yrs.

The Grizzly version of this is single phase and only 5 speeds. Not good. You need that low end 100 rpm speed for milling on occasion.

Both these mills are knee mills. The knee traverses up and down on the dovetailed column.

Bench mills like this one from Grizzly are ok for the home shop but you will bump your head on the ceiling much more frequently due to the limitations.

http://www.grizzly.com/products/2-HP-Mill-Drill/G1006

This is the Grizzly version of my mill. You can see why $1,700 in a used mill was more practical....

http://www.grizzly.com/products/Mill...wer-Feed/G6760

Used mills...

Clausing $2,500. A full size "Bridgeport" type with a 9x42 table. Clausing are very good machines.

http://cgi.ebay.com/5902-CLAUSING-KO...item414f7127df

Used Bridgeport for $2,600.

http://cgi.ebay.com/Bridgeport-J-Hea...item1c12a27281

Index and Wells-Index are very good USA vertical mills. There are some early Index that came after mine, Model 45, 55, 745 that have more features than my ancient Model 40. Wells-Index is still in business in Michigan.

http://cgi.ebay.com/4248-WELLS-INDEX...item414f710a01

Vertical mills are not cheap nor usually inexpensive. That's because they're work horses. They make money. If you enjoy doing this then it's worth going into debt to get these things, IMO. I sold guns to buy my lathe and mill. About $7,000 worth of guns. There is no money better spent.

Though I've spent the last year making scope mounts my experience is in general machine shop meaning all kinds of jobs. I like the challenge of having a wide spectrum of things come my way to do. I'm interested in steam engines, electric vehicles, electronics. I'd love to scratch build an electric motorcycle with a side-car for extra batteries. And I'd like to build a couple single shot firearms from scratch.

A 10x18" wood lathe goes well in the metal working shop.

Dutch

I sold my EMCO Maier Maximat super 11 several years ago, was stupid of me as it was a great quality combo machine I had bought new in 1982.

I had a Smithy, it was Ok but I was glad when it was gone and I got a proper lathe and mill.

I had the 1239 I think it was called.

Replaced it with a Bridgeport, then saved up and got a used 12x36 import lathe

ok guys i got to go get some alka seltzer! i got lots of room but not a lot of bucks. thanks for sharing the photos, very nice. i'll come across the right one sooner or later.

skimmerhead

Cheap things are not good and Good Thing's Are Not Cheap

the worst part of getting old; is remembering when you were young

The small combo machines have all the faults mentioned above. But they do have one benefit. It let's you do something instead of just dreaming about doing something. You're not going to do anything fast, and you may have to reset the machine a lot, but if it's a hobby who cares? If you find out you like doing what you're doing then you can always upgrade to a small lathe and a vertical mill.

While you have one you can teach yourself how to do a lot of creative things. I would compare the little combo machines to a lot of Lee products - they're cheap enough to get a lot of first-timers into the hobby and are perfectly adequate for a lot of people. For those that like it, better, more capable equipment is out there.

If it's all I could afford I'd look for a used one, learn to use it, and save up for better equipment. You can always sell it to somebody later for a down payment on a used Bridgeport without taking too big a hit. Meanwhile you could trim cases, hollow point bullets, make sight bases, cut dovetails, ......

Think about this just as a historical comparison. A gunsmith or machinist of 200 years ago would have been tickled pink to have a modern combo machine, 'cause it would have been way better than what they had available at any price - and look at the quality items they produced. It's more the man than the machine.

Just my opinion.

good opinion! they would have keeled over, iv'e some time on some big machines, during the winter i'd go work at a shipyard, being certified in pipe, plate, aluminun, steel and stainless welding they always had a spot for me. used to weld a lot in the machine shop, on tug boat shafts building up journals to machine down. 2" to 8" shafts and any thing else you can think of. the machinest used to teach me on smaller jobs. so i know enough to get my self in alot of trouble. its been so long since i done that if i tried to make something now and put together it would probably be easier putting socks on an angry rooster. thanks for the opinion.

skimmerhead

Cheap things are not good and Good Thing's Are Not Cheap

the worst part of getting old; is remembering when you were young

For me the Smithy was not a cheaper option, I think my money would have been better spent originally on something used/better quality.

There was actually very little difference between what I sold the used Smithy for and what I paid for the used Bridgeport.

At the time I needed a better mill and wasnt using the lathe much so loosing the lathe for a few years till I saved up wasnt a problem

I see good used equipment in the local classifieds and on Craigslist that is a bargain.

You can get better equipment without spending more money

Having used a Lathe/mill combo, I would not recommend one. They do neither thing well. I would find a used lathe and mill. My import 9x20 is OK as long as I don't take heavy cuts, but I really want a larger lathe with a bigger spindle thru hole. Using modified a mini-mill right now until I find a real mill. After that I will replace the lathe as well.

-yarro

can't wait to see your projects

First off:

1-be VERY patient and start checking Craigslist. You'll see some bargains out there! I've seen nice looking bridgeports for well under $2K. Just have some cash and a truck ready to grab. I got an Atlas 10X36 with change gears and tooling for $300. Deals can be had.

2-What are you using it for? This is perhaps the most important thing not asked here. You may have a great fit size wise with the combo setup or find out its way wrong. IMO if I was doing gun smithing a 36" swing is where I'd want to be. This lets one do rifle barrels between centers effectively among other things. Not sure on the milling side. My advice is having an idea of what you need here before you buy it. Otherwise it's kind of like you asking us about buying a vehicle and how it will suit your uses. I mean, it could be that you have 6 kids and a 20 foot RV you want to haul around and the guy telling you to buy a Camry isn't going to really be giving you good advice.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |