What I do is first make a dummy rd ( old steel cases work well if shot in the same gun) to find the max oal. Then I pp'er the boolit I'm going to use as far out toward the nose as I can, seat this in another case to oal, try to chamber it. If it wo'nt I guesstamate the amount I need to trim off the nose. Using a sharp shop knife I'll trim & try until it will chamber with a slight force to close the bolt. I usually run a cleaning rod down the bore so the boolit doesn't pull when I open the bolt & check how much the rifling shows on the patch. You can then lay your boolit next to this round to see how wide your patch needs to be, I tuck mine at the base so you might want more width if you twist your tails.

One thing to be careful of, make sure you have enough clearence at the neck to allow it to expand when fired. I measure a fired (that gun) case neck outside & a loaded neck to make sure it will work.

I've used this from 6.5 swedes to 45-70s, works for me.

|

|

|

Reply With Quote

Reply With Quote

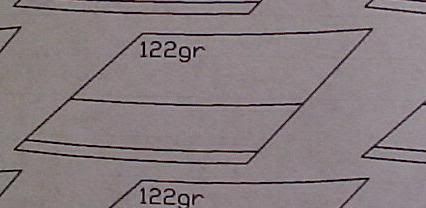

I would suggest a 30° angle off the certical. Easier to wrap - for me.

I would suggest a 30° angle off the certical. Easier to wrap - for me.