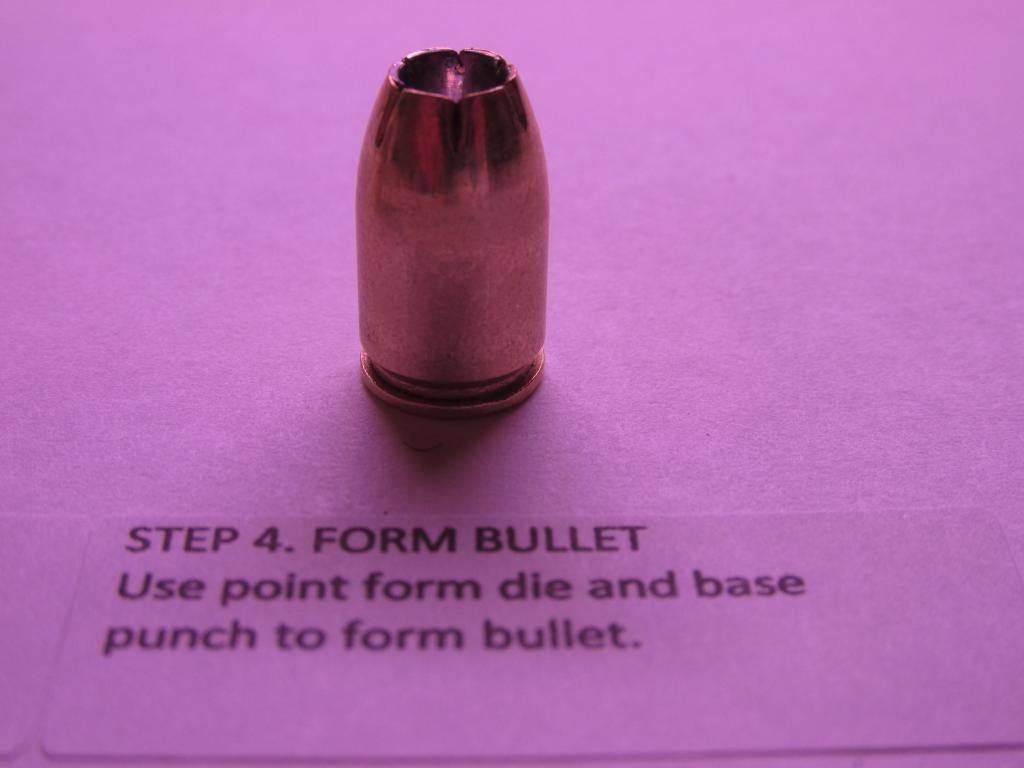

They should be the same as an equivalent weight hollow point jacketed bullet.

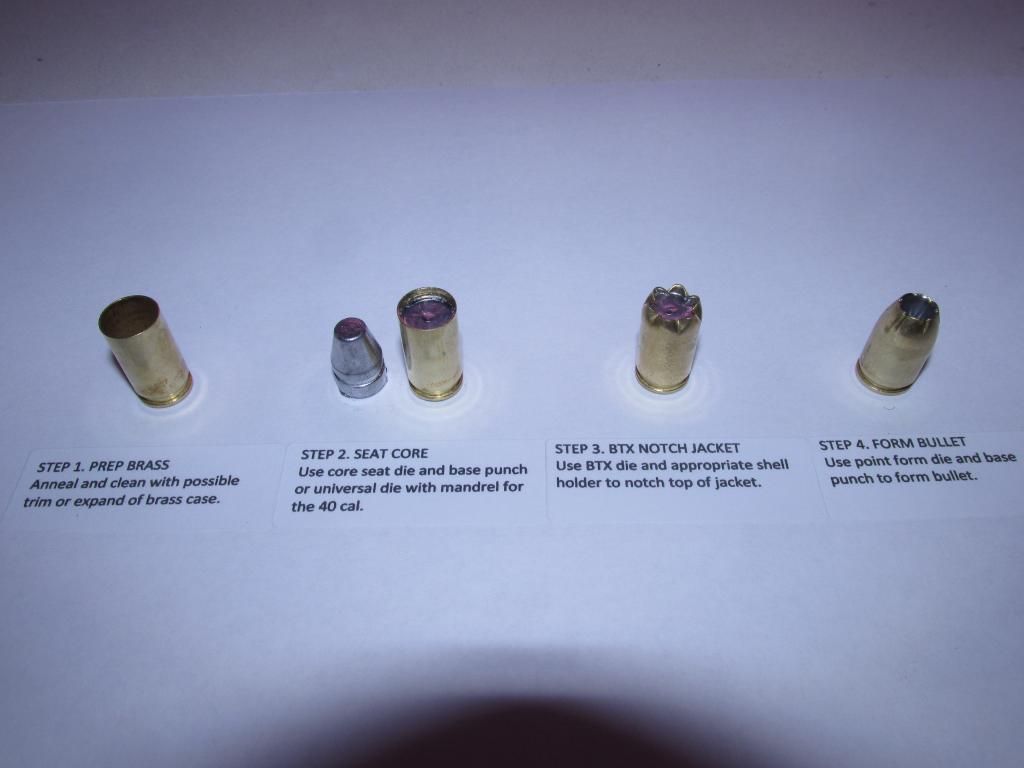

I got both his 44 and 40 dies months ago. I've only made a bunch of the 44s up. They shoot great. I going to make some 40s no that I just found a glock 23 gen4 EXO. These will be my carry bullet. I'll post progress pics.

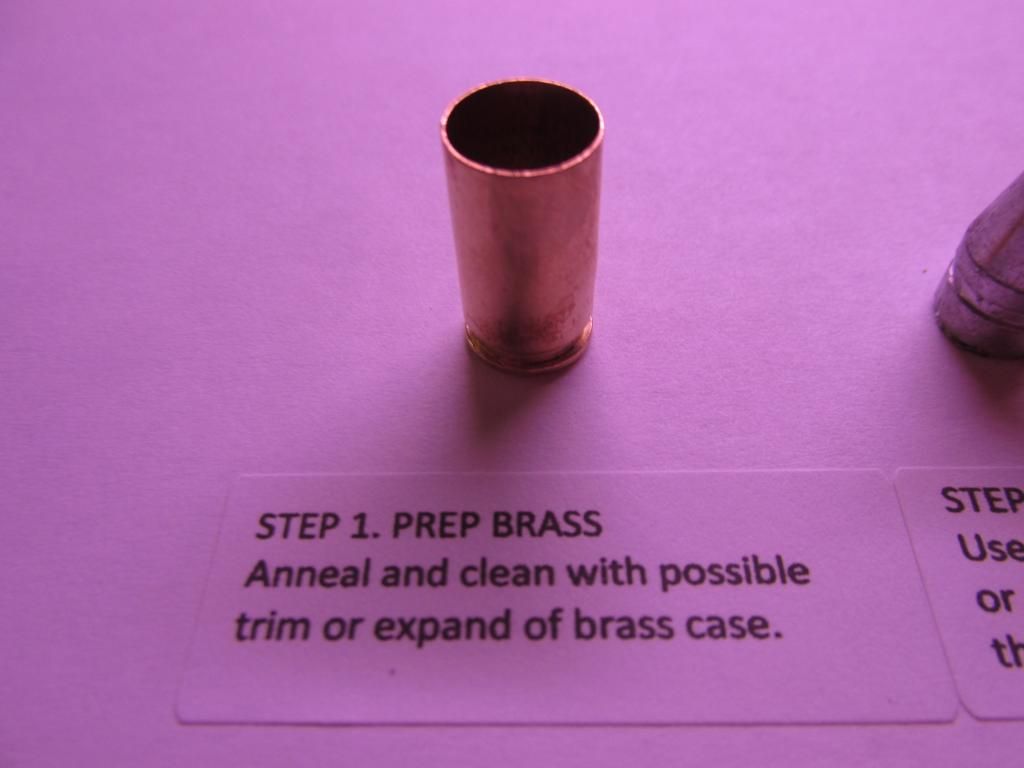

Though I've already annealed the brass, and its soaking in citric acid right now.

|

|

|

Reply With Quote

Reply With Quote BT Sniper

BT Sniper

In fact this is where I may need some wisdom and knowledge from those of you that have been doing this longer than me (which would be all of you)

In fact this is where I may need some wisdom and knowledge from those of you that have been doing this longer than me (which would be all of you)  . I machined down a 124 grain Lee mold and it now drops a 112.5 grain core. That is making a 170 grain bullet that is .650 long. Prefer them over the heavier bullets that are .700 long that I was getting with the 120 grain core.

. I machined down a 124 grain Lee mold and it now drops a 112.5 grain core. That is making a 170 grain bullet that is .650 long. Prefer them over the heavier bullets that are .700 long that I was getting with the 120 grain core.