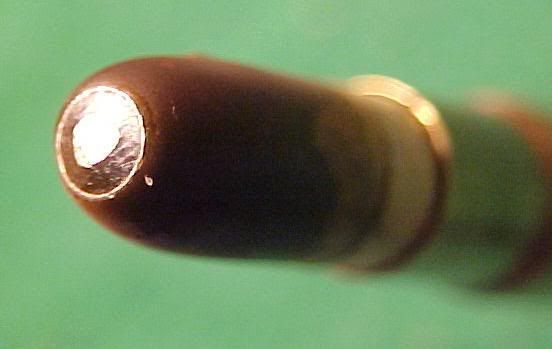

Just made a new nose punch for my adjustable 25 mold and using my latest alloy mix, this is what I get.

118gr PPCBoo core.

Firstly, the alloy casts terribly!

On the up-side, the boolit has a very convenient nose ogive/shank junction ring. Quite by accident, this turns out to be convenient for aligning then patch! (So far, I have only patched it dry, then wet by dipping. A grerat way to apply the patch on such a tiny boolit!)

The first test firing.

Those are the recovered patch bits inside the circle.

|

|

|

Reply With Quote

Reply With Quote

But no, it was purely by accident. But it's a trick I plan on using again!

But no, it was purely by accident. But it's a trick I plan on using again!