Haven't worked up a load yet but loaded 50 up one grain below max with surplus WC846 (55gn using Blackmon dies). Shot a 12x scoped varmint AR off a rolled up blanket on hood of my truck - 10 shot groups were 1 1/2" at 100yds. Would have been sub-moa if I would have benched it.

|

|

|

Reply With Quote

Reply With Quote

(It only looks skew).

(It only looks skew).

I'll try that trick for my next one!

I'll try that trick for my next one! I really need stop and think before jumping in!

I really need stop and think before jumping in!

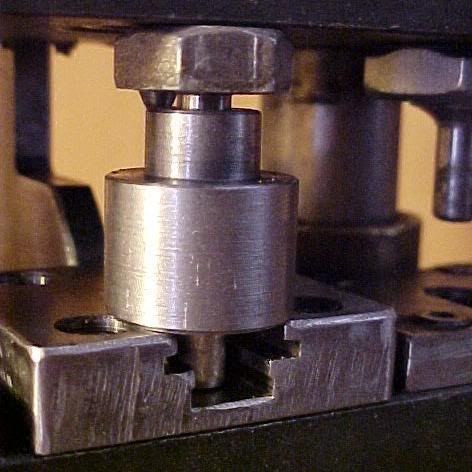

) I tried slightly modifying the first ejector but it was too hard, so I made a new one.

) I tried slightly modifying the first ejector but it was too hard, so I made a new one.

)

)