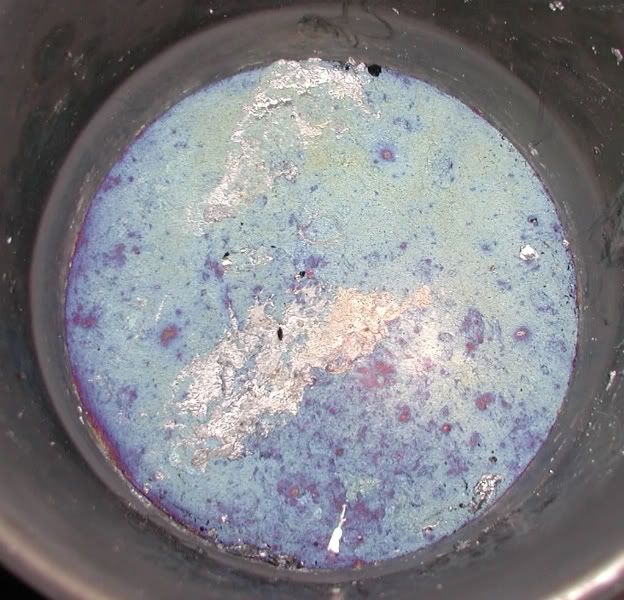

Thanks to a crab cooker and a ss pot, I was able to melt 50lbs of nasty, dirty oily ww. Both the clip-on kind and the stick-on kind. I removed all the clips and solid junk that floated to the top, along with some ash I suppose was left over from rubber burning off? I expected a lot of the tin to oxidize on the surface and I figure that can be re-introduced via fluxing, but there's this layer of blueish-green on ther that doesn't seem to want to flux back in.

Did I wait too long to flux, is there a point of no return where it's too difficult to de-oxydize the stuff, what can you tell me?

Even if I ruin it, no big deal this is a learning process. But I would like to know what to do next. It's cooling off as I write this, will I be able to salvage this as useable alloy?

|

|

|

Reply With Quote

Reply With Quote