Well, not knowing what the hell I am doing ..... this is my first ever patched bullet.

From the mould

Patched, lubed and loaded

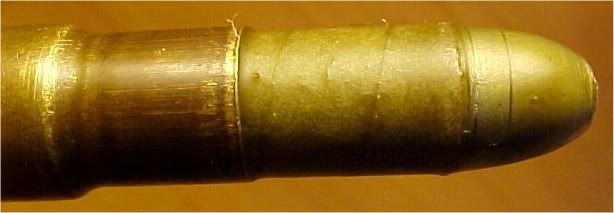

Recovered bullet!!!

Primer to show good pressure (Zero leading or fouling of any sort in the bore!)

PS That's a 30 year old case that's still going strong! Used exclusively in a 107 year old rifle!

|

|

|

Reply With Quote

Reply With Quote