This buy is now closed

This is a rerun of the earlier group buy. If you missed out on the original buy, here is your chance to get one of these excellent molds. To sign up, PM me your email address and zip code. I will post your zip code here.

This buy will run till our turn comes up with Mihec. When it does, the buy will be closed and Mihec will send out invoices via paypal to the address you provide me with, so the email you send me should be your paypal address.

Price will be $120 plus $20 shipping for a four cavity brass mold with the Cramer hollowbase system.

A solid version (no cramer system) is available for $85 plus $20 shipping. You must make clear to me that you want the solid version! Make sure I have noted it next to your zip code!

This mold is literally like ten times faster than the old single cavity pin type that Lyman made. Don’t miss out again.

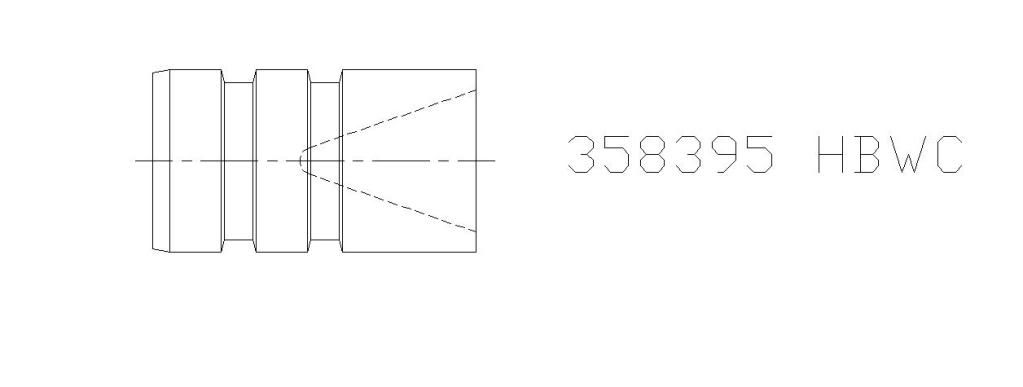

Here is a graphic of the mold. Target diameter will be .360 and weight 148 gr. with WW.

Zip Codes

50401

04093

37209

S7j 2X9

46983

49331

89012

20165

84057

24426

01906

15241

74501

01564 - SOLID

48092

77355

77070

71343

97213

91916

98802

48889

99901

52732

78666

68601

83276

78232

89086

4868

4870

64058

19085

42261

39666

|

|

|