The links don't work for me. Sent you a PM.

|

|

|

I like it, should I looked here before buying one.

I got the giraud. don't get me wrong, I like it, but sometimes the mechanical parts get stuck (the slides) and it burns the case and overworks the motor.

couldn't figure out why, but I like your setup much more. probably can anneal more cases than the giraud?

The cycle time is cut in half vs the Giraud because of the use of two torches vs one but that is only a time concern.

Well, I was going to experiment with mapp gas on the giraud, but for that I need the slide to be faster but the motor is already at max speed,

Do You still have any blades for the annealer machines W/the layout drawings?

If so could you please send payment info to perkbilt@gmail.com

jmorris could you send me info.

Last edited by Dave Bob; 08-11-2014 at 11:51 PM.

What is the diameter of the blade you make?

It Is Intuitively Obvious To The Most Casual Observer With The Least Amount Of Experience

My Feedback

http://castboolits.gunloads.com/show...hlight=Fla9-40

Just a quick note to ya' all, Surplus Center, in Omaha NE has the small geared motors that you are using and they are cheap! Lots of other good stuff too.....

Hi jmorris,

I am trying to get in touch with you about purchasing a disk and plan set for an annealer. I sent you a PM but not sure it went through. Do you still sell them? Are you willing to ship it to the T0J 0Z0 postal code of Canada?

Thanks,

Kraken Fan #69

Last edited by KrakenFan69; 11-22-2014 at 03:30 AM. Reason: spelling

jmorris

I would like to order a "blade" and plans. This looks really great and the machines built are awesome.

I as well would like to order a blade and plans.

Thanks,

Lee

Gathering the parts for my build and realized it was not clear to me how the motor shaft is coupled to the shaft that turns the arm for advancing the blade. Can anyone help with that ?

The plans sent with the blade show that the "drive wheel" is drilled and tapped and the set screw holds it directly to the motor shaft.

Like in this photo that shows both the part and the drawing. From the album linked to in the first post in '09.

The prototype machines I have built for production use 1/2" aluminum bar stock drilled then reamed to 5/16" and have an 8-32 set screw that mounts it to the motor shaft. And the 10-32 socket head cap screw is threaded in from the bottom.

Some folks have used a set collar welded to a section of steel with a bolt in it for the job. Like this one.

http://vid121.photobucket.com/albums...borganneal.mp4

Last edited by jmorris; 02-15-2015 at 02:48 AM.

Thanks for the quick reply ! Did you find it necessary to file a flat spot on the motor shaft for the set screw ?

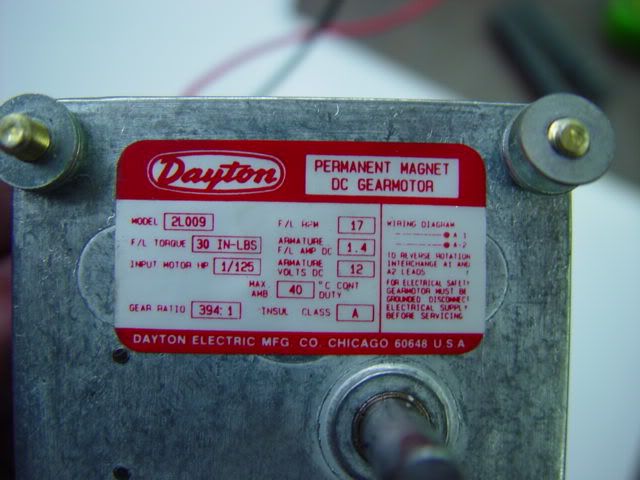

No, the Dayton 2L009 that the plans are for has a "D" shaped shaft, align the set screw with the flat. Wiggle it back and forth as you seat the set screw and you will be good to go. There is very little torque involved, just what it takes to skid empty cases on a smooth surface.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |