How many of you guys trim brass for the carbine?

|

|

|

How many of you guys trim brass for the carbine?

I check the length every time and always have some that are over spec and needs a trim. Not sure why such a thick straight case grows so fast but it does.

And the thick brass makes using a hand powered lathe type trimmers a real pain. I use the Lee system with the cutter chucked into a drill press.

Same for me too. I check every piece after sizing and always have some that need a trim. I will say though, brass length was way more important for the .30 carbine Blackhawk I had than my Carbine. Even a Ďthouí over max would prevent chambering in that pistol.

Sent from my iPhone using Tapatalk

I was always more worried about an out of battery discharge in my carbines. Once I realized it only took a few shots to get the cases to over max I now check each case after sizing.

GI carbines are nearly impossible to get an OOB discharge with due to the way they are made. There is a bridge inside the receiver that stops the hammer from striking the firing pin. secondly there is a rim in the rear of the bolt that prevents the hammer from reaching the firing pin unless the bolt is rotated to a safe "closed" position. Commercial carbines my be lacking those features. I check my brass for proper length every time I reload and run anything close or over through the trimmer. It avoids the dreaded failure to fire problem. I also suggest that you get a go/no-go set of gauges and check the headspace in your carbines. Well used ones can develop headspace problems although it isn't common. Get a field reject gauge at the very least. Keep it on the safe side.

I friend of mine had an out of battery fire with his carbine. He was telling me how hard it kicked him and I laughed at him and didn't believe him till he showed me his shoulder a few days later and it was black and blue. Turns out it was an out of spec op-rod and after swapping it he never had another problem.

I am very familiar with Carbine and Garand function and troubleshooting and I am still not 100% sure why an out of spec oprod would cause this failure but the point is not all of the fail safe mechanisms can work with a well worn 80 year old rifle. Since then I have been very cautious and always checking my case max length and found they get over spec fast.

I check every .30 carbine case. It takes a lot of time but needs to be done.

I check them each time I load a new batch. On the advice of another member here, I made my own case length gauge. It makes the job a lot less tedious for sure. I toss the ones that need trimming into a coffee can and trim them when there's enough to bother with. My finding is that the cases stretch mostly upon sizing, so even though I'm using carbide dies I will still use case lube. I'm convinced that it helps.

As for the lathe type trimmers being tough to use, I found that sizing and expanding the necks and THEN trimming makes it a piece of cake.

+1 for expanding before trimming. It is a lot easier that way.

Only Ďexpandingí I do is flaring the case mouth and that occurs after I trim.I kind of figured flaring would shorten the COL slightly. Trimming is something I really donít enjoy doing. Part of the reason is my Hornady Lock & Load trimmer. Locking the case in snugly moves the case slightly off center resulting in a not perfectly square cut. The Hornady tech guy said the case should be able to turn while trimming so I use a little finger pressure to allow some rotation while trimming. Not my idea of a well designed machine.

I have no ideare "How many of you guys..." -- BUT I ALWAYS have brass length as my number 1 priority! Waaaay back -- maybe 40 years ago -- I got my first M1 Carbine and had miss and hit firing -- plus, all sorts of ftf, stove-pipe, and other challenges. A super local fellow -- active US Navy at the time -- was home on leave, and gave me some advice I never strayed from. I lost

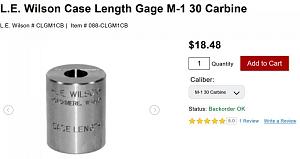

the scrap of paper he wrote the numbers on, but had transferred them to a sticker I still have on my die storage box. I've pasted it here. Perhaps you/others have better luck than I do -- BUT, all .30 Carbine brass -- new, or fired, gets "run" through my L E Wilson case length measurer, followed by the trimmer if even a blonde hair too long; and, discarded if too short. Here's the sticker:

Annd, here's a current ad re Gauge I employ:

Last edited by georgerkahn; 04-14-2024 at 09:01 AM.

Good information I will take to heart when I reload for my Auto-Ordinance new made carbine.

I understand thatís the procedure as set forth in the instructions. My digital calipers are set to 1.290Ē. The L&L trimmer is set to cut to 1.289Ē. If I check case length around the circumference of a case thatís been trimmed according to the HORNADY directions one side is shorter by a few .000Ēs than the other. one side of case is a tight fit in preset calipers while other side is loose.

And yeah, my cutter shaft doesnít wobble and Iím using the correct pilot.

My conversation about this with Hornady occurred after the purchase about six years ago. I spoke to (I think) Richard who I was informed was the designer of the tool and part owner of the company.

His suggestion to allow the case to rotate slightly while trimming does result in a more square cut of the case mouth. Maybe part of the length variance Iím seeing is because the base of the brass isnít exactly square, I havenít checked that.

Maybe Iím just too obsessed for my own good!

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |