It all started in January at a local gun show where I stumbled on an old pair of Marlin Ballard rifles. One was a 22LR Schutzen and the other was a No. 9 Union Hill gun that appeared to be a 32 cal gun. The case colors were still strong, and the bluing on the barrel was nice. The bore was gorgeous! Made a deal and bought the 32 cal. A great fellow on this site, Marlinman93 looked a photo I posted of the rifle and told me it was a Marlin built Ballard with a forged receiver manufactured around 1886. He was so gracious to help me. Strictly a target gun these rifles were either 32-40wcf or 38-55wcf. I dropped a 32-40 cartridge in the chamber and closed the breech block.

Now the challenge begins. Where do I get ammo? Drove a soft 36 caliber round ball through the bore. It measured .330" Looked all through my moulds. Nothing even close to .330" Ordered a set of dies. Found an old Lee 308160R single cavity mould to use as a donor. Turned up a piece of 1/2" square stock 01 die steel to resemble a round nose 32 cal with an ojive conforming to the 30 cal. Lee shape but with grease bands slightly larger than my .330" groove depth. Milled several flutes on the cuttter and heat treated it. I chucked up the new cutter in my DeWalt drill and slowly turned it with a lot of cutting oil. The lead pot was heating up while I degreased the freshly cut mould. The new boolit mould drops em at .335" Ya Hoo! Had to make a new sizer for my Lyman 4500 luber-sizer and a new top punch that fit the new casting. The newly sized boolits came out at .333" Resizing a few old cases the whole length made the case mouths too small for my fat boolits. Just partially sized the brass. Made a new expander to flair the case mouth. Seated several boolits over 8 grs of Unique to try. Of course the new cartridges would not chamber. Thought about breech seating the new boolits and loading a charged case behind it. Nah! Wanted loaded ammo so that this rifle with the old telescope could be loaded easily. Woodchucks will be out in June when the hay is mowed.

Still not being able to shoot my 150 year old Ballard I had to be patient. Measured the neck of my newly crafted ammo and figured a .355" straight reamer would open the chamber neck. M & M Tools in Mentor, Ohio supplied a straight chucking reamer. Had to wait a few days for the new reamer to arrive. So with a small hand chuck I carefully opened the chamber neck till my cartridges chambered.

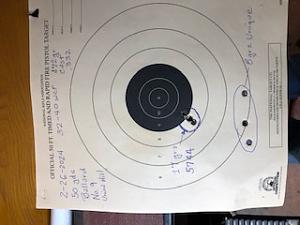

Next day was range day to try out my 19th century target rifle. The old brass telescope is about 6X. I bore sighted the old rifle at 50yards. The first loads were the 8grs of Unique with my 172 gr homemade boolit. They were on the paper. My next try was 17 grs of 5744. Wow! All three were touching. Success! Still plan on working the sizer die over so it is easier on the brass. Can't wait to to bang a few varmints this summer with my 19th century target rifle with home made ammo.

|

|

|

Reply With Quote

Reply With Quote