I'm using a oversized jacketed bullet .431 verses a .429.

Even with an bell expander will it be enough with the .431 verses a .429 ?

|

|

|

I'm using a oversized jacketed bullet .431 verses a .429.

Even with an bell expander will it be enough with the .431 verses a .429 ?

Last edited by castmiester; 02-19-2024 at 11:13 PM.

Neck tension will not be a pressure issue.

Chamber pressure due to a oversized cartridge would be the only thing I would worry about, and you are well within SAAMI specs, so you should be fine on that account.

https://i0.wp.com/www.theballisticas...44-Rem-Mag.jpg

~~~~~~~~~~~~~~

“If someone has a gun and is trying to kill you, it would be reasonable to shoot back with your own gun.”

― The Dalai Lama, Seattle Times, May 2001

Ok... I'm trying the cowboy expander over the jacketed expander. I'll see the difference.

Update.... .004 neck tension with the cowboy expander. Is that more like it ?

I'm stumped..... After sizing with the carbide die the standard bell/expander slips right in the case, no expanding !? I don't get this ?

Ok the Saami drawing shows .004 bullet seated neck tension and .354 OD case neck. Forgot about looking at the drawing. Chamber pressure from bullet having the bulge otherwise I take it? Thanks bud. I'm at .002 less than the drawing bullet diameter. Pretty much right there with my bullet.

Don't get why they don't use a Jacketed industry standard .429 ?

Last edited by castmiester; 02-20-2024 at 12:07 AM.

I'm not sure what you are after?

The books tell us to strive for .002 ,but every gun and/or load may dictate more or less neck tension. Different neck tensions will likely effect POI.

~~~~~~~~~~~~~~

“If someone has a gun and is trying to kill you, it would be reasonable to shoot back with your own gun.”

― The Dalai Lama, Seattle Times, May 2001

Thought neck tension was an issue for pressure.... but it's chamber pressure with case size after bullet seating... thanks for the reminder, been awhile.

I landed at .004 neck tension .002 under the case OD after seating according to the drawing. Neck tension .002 like you said but .002 under Outside neck diameter after seating. Getting lost with numbers from .001 difference in bullet diameters. Don't get that one.

Ahh..... case neck thickness variations.... spoiled with Lee collet neck sizer with my rifle sizing. Always the same with those OD dimensions.

Last edited by castmiester; 02-20-2024 at 12:16 AM.

You realize that you cannot achieve 0.004" neck tension, right? Brass does not have that much elasticity before it deforms. Have you ever seated a bullet, felt significant resistance, then pulled the bullet and reseated it. It goes into the case much easier the second time. Why? The bullet further expanded the case neck during seating. The elasticity of brass is only about 0.001"+/- 0.0005" depending on alloy/work hardening. Any additional constriction of the case neck just gets expanded further by the bullet.

Is there a benefit to greater than 0.002" less than bullet ID, probably in preventing setback, but not for bullet pull under recoil. A crimp also helps bullet pull some, but most resistance to bullet pull results from the 0.001"-0.0015" of neck tension, regardless of how much smaller the case neck was prior to bullet seating.

Straight wall pistol size dies do not have an expander on any of the dies I have... All they do is compress the OD back to "spec".

Measure outside neck diameter, before & after seating a bullet. Minimum is .002" better up to .004" for big magnums. 460 & 500s.

Different brass, different NT. Spring back is the cause.

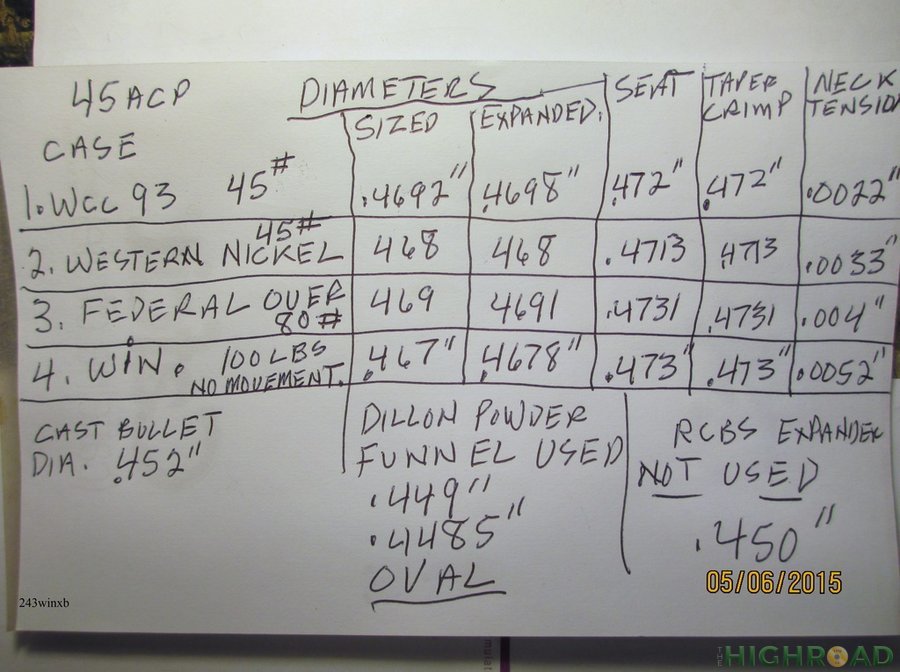

My 45 acp test-

A good question, but I intentionally look for and purchase the .431" bullets for use in my 24" Rossi R92 which has a very generous barrel. Does it really need the larger diameter bullets? Probably not but I found a really nice load and like the results. I have not tried them in either of my 44mag pistols.Don't get why they don't use a Jacketed industry standard .429 ?

Note: I use the normal expander.

“Some people spend an entire lifetime wondering if they made a difference in the world. But, the Marines don't have that problem.” Ronald Reagan

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |