I picked up a nice Pedersoli .45-70 Silhouette earlier this year and thought I'd try PP. That's probably as close to Quigley's rifle that I'll ever own. I already owned an 1871 H&R Buffalo Classic but a pound cast of the chamber looks like the leade is too sharp for PP so I'll likely stick to GG boolits for it. I also have a couple of Trapdoor rifles but their abrupt transition from throat to rifling looks like they may not be good PP candidates either.

I'll probably size a couple of different GG boolits that I've cast down to the size I need for the Sharps (.4505") even though I'll have to run them through a couple of progressively smaller sizer dies. I know, it's not the best method as far as accuracy but I have the boolits and sizer dies already. I'm in the process of ordering a mould/s for slicks to patch but this will allow me to get started while waiting for moulds to be made and shipped to me.

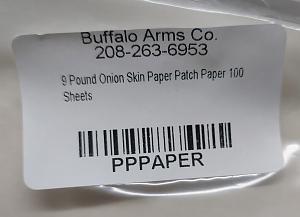

The question I have regards the paper. I ordered a roll of Seth Cole 55W 8lb tracing paper which measures .0015" as I expected. My math told me that I'd need a bit thicker so I ordered 100 sheets of 9lb Onion Skin from Buffalo Arms. When the Onion Skin arrived I measured it with a calibrated Starret 0-1" micrometer. The Onion Skin only measures .0015" just like the 8lb 55W. I went back and checked the Buffalo Arms website and it does indeed advertise the 9lb Onion Skin as .0020" thick. I measured other sheets to be sure the one sheet was not a one-off but it was not. The 9lb Onion Skin is .0015" thick. Has anyone ran up against this?

What other paper could I use that is just a bit thicker than the 8lb .0015" 55W? I may not need a full .0020" thickness but I do need more than .0015" thick if I am going to only use two wraps.

https://www.buffaloarms.com/9-pound-...h-pppaper.html

|

|

|

Reply With Quote

Reply With Quote