On page 145 in his excellent book, "Loading Cartridges for the Original .45-70 Springfield Rifle and Carbine" (3d Edition), Spence Wolf says to cast a 460210 Rapine bullet from 80:1 alloy to use in a gallery load for 50-100 yard ranges. I don't have that exact mold but one that is very close made by Tom at Accurate which is his 46-210RN. My question is in regards to the alloy that Spence says to use, namely an 80:1 (or "1 in 80"?). I've never seen that alloy listed anywhere else. Is it basically the same as a 40:1 alloy with half the amount of tin?

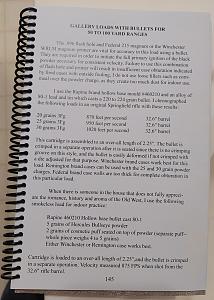

Also, why 80:1? Is that to keep the hollow base bullet soft to insure complete obturation of that hollow base? If so, would not an alloy like 40:1 or even 20:1 be adequate for complete obturation as long as the alloy contains only tin and lead and no antimony? The powder charge for this "Gallery Load" is 20, 25, or 30 grains of FFFG or 5 grains of Bullseye. Could the boolit alloy be so soft due to the very low pressure charges used to propel it?

If the very soft 80:1 .460" boolit is seated into a case that has been expanded to .460" and the case is even slightly taper crimped wouldn't that squeeze the boolit down to less/much less than .460" thereby negating the use of a .460" boolit vs .457"? Spence repeats several times throughout his book that a .460" diameter (20:1) is required for the Trapdoors, both the 420gr and the 500gr. When I figure out how to measure a three rifling pound cast I'll verify that in my two TDs.

Note: The 46-210RN boolits pictured are cast from 20:1 to test their diameter which is .460". I hope a softer alloy would not reduce the diameter appreciably.

|

|

|

Reply With Quote

Reply With Quote

Chill Wills

Chill Wills