|

|

|

In school: We learn lessons, and are given tests.

In life: We are given tests, and learn lessons.

OK People. Enough of this idle chit-chat.

This ain't your Grandma's sewing circle.

EVERYONE!

Back to your oars. The Captain wants to waterski.

I have some permanent type, some call it foundry type. Anyway it looks like what you have. Several years back I poured some boolits out of that stuff for my 303 Brit, they sure were purdy. Hard as Chinese arithmetic. Dang things broke off at the case mouth when chambering.

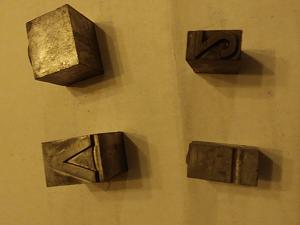

Foundry Type has a notch in the back of it. I can't tell by the picture if yours does or not. It may be Mono Type. Either one will be very hard!

Some of this has a notch in the back. Most do not. Have been doing some research. It is confusing. Articles seem to indicate mono however most include caveats. These have a flat foot and a low notch in the back indicating mono. Article states foundry type has a grooved foot and a center notch. I have approx 45 lbs. Do both have value to us as casting material (sweetners). I would like to offer for sale but want to make sure I do not misrepresent it. Probably need to find an XRF gun for analysis. Will try to link the article for anyone interested. My thanks to the Masters who have responded. https://swamppress.com/pdf/Type%20Identifier-new.pdf

Both are valuable to casters, especially ones that are sitting on tons of pure lead. Also anybody looking for very high antimony lead. All those people wanting to dissolve antimony into lead? Well this is a much easier and more accurate solution.

Years ago I got an assortment of type metal. There were some pieces that looked like foundry type. But when I added them to my pot they didn't melt at normal casting temperature. I removed them from my pot and later tried to melt them with a torch. They appeared to melt similar to aluminum. These seemed to be lighter than lead alloy but heavier than aluminum. I have no idea what they were.

For sure NOT aluminum. Positive its a lead alloy, Just not sure which one. I'm leaning towards mono.

I would alloy it 8 pounds pure lead and two pounds type. You don't need to add any tin since it is high in tin. Been there done that.

ACC

Stopped at the closest scrap yard today. They did not have a XRF gun since the are a satellite yard. Suggested I go to the next town over as they do have one and told me they would scan at no cost. Maybe In a couple days. Here's a couple more pics. Larger block lettering is 3/4" tall, just FYI. I mainly cast for .45ACP and use WW and range lead. Sorry crappy pics.

Words are weapons sharper than knives - INXS

The pen is mightier than the sword - Edward Bulwer-Lytton

The tongue is mightier than the blade - Euripides

Way back when, I was shooting bullseye competition, I cast some 38 WC bullets out of a mystery alloy of handset printer's type. I was shooting at a bullseye 50' indoor match, with my 52 S&W. On one of my targets, I had an extra hit. Unknown where it came from. The range officer gave me a reshoot. On that target I had an extra hit also. Since no other one was shooting, it had to come from my gun. The only explanation was, my bullets were breaking in half around the circumferance, because they were so hard and brittle. Fortunately I did not load too many of them. The remainder went back in the lead pot, mixed with some pure lead.

40 years later, some of my former team members still talk about that event.

Well, If they were both X's I would have claimed magic and wanted them both scored!!!

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |