I offer the following information for no other reason than to show others how I have gone about the problem of obtaining barrels for the SB2 frame that are not offered by H&R.

Most of the work to this date has been on straight wall black powder cartridges for the Buffalo Classic. This covers .32-40, .38-55, .40-65, .45-70 and .50-70.

H&R Offers a .38-55 and .45-70 barrel but the rifling is very shallow and in my opinion

just OK for cast bullets.

The biggest cost is also the part that needs to have the most attention – The Barrel Blank. The first barrel that I built was on a Douglas (304 776-1341) 4140 .40 cal. 1-16 twist straight blank. This has proved to be a very accurate barrel. To date the only work I have done with it has been out to 200 yards. The biggest problem with using a straight blank is contouring it to what you need. I had a local custom barrel maker (Bull Barry Barrels) turn and chamber it for me. Part of this turned out to be a cost that I didn’t need if I would have spent more time to think things through.

The second barrel was a Badger Barrel (262 857-6950) .38 call Octagon. I faxed Ernie a drawing of what I wanted and he furnished it in a very timely manner. The cost was less than a straight blank and having to turn it to what I wanted. This barrel has one of the smoothest bores I have seen. Again only shot it out to 200 yards but have got some very good groups. My suggestion would be to purchase a Barrel that is contoured from the maker. For ease of machining I have the barrel short chambered, cut to length and crowned before any more work is done.

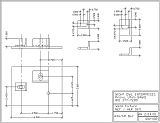

The next big problem is the lug that welds to the barrel. I produced a drawing to have this part machined, see attached drawing 000-001. The most economical way to have this part made was to go to a shop that works with CNC equipment. Again I went to a local shop, Advanced Manufacturing Technologies (801 973-9462) to furnish me this part. The cost for one part was just about as much as ten so I ordered ten. When I made the drawing I tried to give my self enough room to hand fit the locking lug. So there is a small amount of leeway in this lug. It has worked out very well for me.

The next problem is to locate the lug on the barrel, to do this I built a fixture. See attached drawing 000-002. To set this fixture I use the stock barrel from the action

that I’m building for. And again there is a small amount of leeway in the lug for hand fitting. After the fixture and lug are in place I use a small C-clamp to hold every thing in place.

Fixture, Lug and Barrel clamped together for welding.

Before clamping the lug to the barrel there is a small amount of pre-fit-up that can be done. I make sure the lug will fit snug in the action on its own. This may take a little polishing to accomplish but just go slow.

The next step will be to weld the lug to the barrel. I had the lug machined from 4130 material and have had real good results welding it to 4140 barrels. The barrel, lug, fixture and C-clamps are all pre-heated to 250 to 300 deg. I use a modified rod oven for this.

The lug is TIG welded to the barrel using 4130 filler wire. I tack weld the side of the lug that you can get to first then remove the fixture, re-clamp and weld the other side. After welding remove the C-clamp and wrapped in a heat blanket to control how it cools and returned to the oven. The oven is then turned down to start cooling. This should take about 8 to 12 hours.

Next is fitting the barrel/lug assembly to the action. This is done with standard gunsmith procedures. The locking lug is over size so it can be hand fit to the action. This is one of those “take a little off” and try type things.

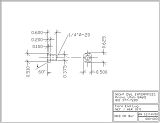

Next is the fore end lug. This is spot welded on the stock barrel. I opted to use a dove tail to retain the lug. See attached drawing 000-003. I had a local machinist turn out ten of these to go with the ten lugs. This can be cut and installed at the same time the sights are installed.

Next the barrel will need to be finish chambered and checked for head space.

Again this is just standard gunsmith procedures. Ejector parts are available from Brownell (800 741-0015) or Gunparts (845 679-2417). Install the ejector parts and check for final fit to action.

All that is left to do is remove the ejector part, polish and blue the finished barrel.

This has been a very educational project for me and I have enjoyed the outcome.

I have come to the conclusion that it is no harder to build a barrel for a H&R than it is for a TC Contender and I’m working on a way to make a adjustable lock for the SB2 frame.

In closing I would like to say that every thing that I have done can be done by any one else. There is no magic to making a barrel like this and I hope this information helps some one else have as much enjoyment as I have had.

Swede-Nelson

|

|

|

Reply With Quote

Reply With Quote

. Jetwrench

. Jetwrench