Iím confused about gas checks on the molds I'm working with.

Iíve read most every thread about gas checks on the forum and I learned about annealing, flaring the check with a carriage bolt, custom gas check dies, "small" ball peen hammers to start the check, .011 versus .014 thick material, expanding the check so it seats properly, starting the check on the bullet shank prior to sizing (I'm using a Lyman 450), after market hardware to start the gas check and even the super glue idea. But what I have on the bench is not adding up. There's a difference in the shank dimensions that I didn't expect and the checks I have work great on some molds and not at all on others.

Iím working with four different molds that I had hoped to use on two new 7.62 rifles. From small to large the molds are the MP 314-140SH, Lee C-155-2R, NOE 312-165-FN-H3 and the Lyman 311299. The rifles are both 7.62x39 Rugerís. One is the Ruger Ranch bolt gun and the other is their Mini 30. So far most all the molds look doable with the exception of the 200 grain in the Mini 30. Kissing the lands they all have the gas check in the neck. All of the heavy stuff will be subsonic. The Ruger bolt gun bore is .3098 and the Mini 30 is .3100. Alloy used is 90-5-5.

Initially all will be shot over a chronograph and through a suppressor so the check has to stay with the bullet. The Hornady and Lyman checks work fine on the NOE and the Lyman. The same checks that fit the NOE and the Lyman perfectly will either not seat squarely on the MP and the Lee or if they do they spin.

To make things simple Iíll focus on the Lee 155.

- The NOE 312-165-FN-H3 shank measurement nearest the body of the bullet measures .2857. Furthest from the bullet body (nearest sprue cut) the shank measures .2854. Both the Hornady and the Lyman seat tight and square.

- The Lee C-155-2R shank nearest the body of the bullet measures .2889. Furthest from the body of the bullet (nearest the sprue cut) the shank measures .2887. Both the Hornady and the Lyman look to be not fully seated and about half of the check spin.

The MP mold leans in the same direction with the shank about the same size as the Lee. If I could flare the check I could get it over the base of the MP shank and if the check material was a couple thousands thicker I think it would grip the shank?

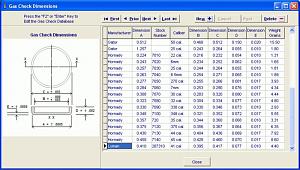

Is that why Pat Marlin sells one check maker for the .308 and another for the 7.62?

Unfortunately sending back the Lee is not an option. Lead time on everything is so crazy I would be waiting a long long time to receive a replacement. And if a custom gas check maker solves the issue I'll only have to wait 3 months. Using a thicker material for the check should tighten up the grip on the shank should it not?

So what Iím asking is can I buy myself out of a bind by buying Patís check making die using various thickness for the check material and if so should I buy the 7.62 or the .308. To me it almost looks like the inside dimension of the check is too small for the Lee and the MP. Thanks, Bill.

|

|

|

Reply With Quote

Reply With Quote