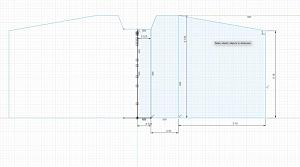

I'm working on a concept for a symmetrical double-ended semi wadcutter design for my 36 caliber 1851 revolver. The idea is to make something that's more effective on the target than a conical or a round ball, but easier to load than both, including for use in paper cartridges. The diameter as modeled is .375", with a weight in pure lead of about 129 grains. Thoughts, feedback, suggestions?

|

|

|

Reply With Quote

Reply With Quote