|

|

|

This is spot on, the barrel slugs at. .357" so I run a .358" boolit but have to seat them deeper than my other 9s. I recently started casting a mp 147gr rn but the seating depth has deterred me from trying it in this gun. it really doesn't need very much material removed thus grinding seemed like a reasonable option.

As to who case hardness barrels any of the barrels that are Melonite treated are case hardened. This is getting to be fairly common in both pistols and rifles. Same for Titanium Nitride surface coating that CZ is using on these. That is the same type of coating used on cutting tools and inserts. It's a surface finish not case hardening

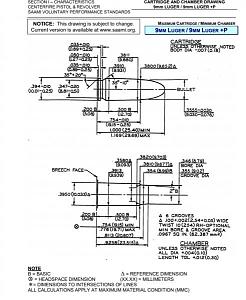

On SAAMI 9mm chambers there is no throat per say. The throat and the lead are one and the same. 2 degrees starting at at .358" with no straight throat.

The Shadow 2 per CZ is the "queen of the IPSC Production Division and the most accurate and fastest pistol of its category in the world".

I don't have a Shadow 2 but I do have CZ 75 Tactical Sport Orange in 9mm and that will give the finest NRA Bullseye match pistols a run for the money.

2nd Amendment of the U.S. Constitution. - "A well regulated Militia, being necessary to the security of a free State, the right of the people to keep and bear Arms, shall not be infringed."

"Before you argue with someone, ask yourself, is that person even mentally mature enough to grasp the concept of different perspectives? Because if not, there’s absolutely no point."

– Amber Veal

"The Highest form of ignorance is when your reject something you don't know anything about".

- Wayne Dyer

This is hearsay, so fwiw, I heard that Jerry Keefer puts .100" of freebore and a 1 degree leade in the barrel of the 9mm that keeps on winning the matches.

I also looked over the SAAMI chamber spec and maybe I saw it wrong, but it looked to me like it called for freebore before the leade ins. I don't have it on this laptop, but I will check it when I get to the other puter.

Personally I view freebore as a tool that holds the boolit square and perfectly parallel to the line of travel, and also concentric to the bore, which is a smaller diameter than the expanded case, it guides the boolit perfectly aligned to the rifling. Not far removed from the front half of a Taylor Throat that they use in revolver barrels. I find that it works GREAT for this intended purpose. I always put a goodly amount of freebore in my throating jobs, enough that the boolit is mostly or all the way free of the case mouth and held in the freebore before it engages the leade ins.

Got a .22 .30 .32 .357 .38 .40 .41 .44 .45 .480 or .500 S&W cylinder that needs throats honed? 9mm, 10mm/40S&W, 45 ACP pistol barrel that won't "plunk" your handloads? 480 Ruger or 475 Linebaugh cylinder that needs the "step" reamed to 6° 30min chamfer? Click here to send me a PM You can also find me on Facebook Click Here.

I am not stating that the SAAMI chamber is the best for accuracy or even that is what CZ is using. Thats why I recommend a chamber cast. I am using the SAAMI chamber since it an easy too locate print of a 9mm chamber that does show what the actual challenge is. That is blind locating an angled surface with a die grinder and cutting a quality lead and or freebore.

I do very little work on handguns other than 1911 for NRA Bullseye and they are a dying breed. I mostly specialize in NRA Highpower, Palma, F-Class and long range bench guns. None of these are using SAAMI chambers. Through the years I have seen barrels with a variety issues the should reduce accuracy however surprisingly they still performed superbly. The exception is throats and lead angles. I have yet to see a throat/lead angle that had issues that perform to expectations.

My guess is handguns are no different. What is different it for handguns some of the applications don't require much for accuracy. The CZ Shadow 2 is designed as a competition handgun and they should be capable of exceptional accuracy. If the OP does things properly that accuracy level may increase. Done improperly it may turn into scrap metal. That's the OP choice. He is asking for advice on how to do it properly.

I tend to agree with you that freebore has benefits if it's done properly. If the OP does opt to cut freebore he still should cut a lead angle. I have done a couple 1911 barrels that started with no lead. The accuracy greatly improved when a proper lead was cut.

SAAMI 9mm chamber print here:

Last edited by M-Tecs; 10-16-2020 at 10:09 PM.

2nd Amendment of the U.S. Constitution. - "A well regulated Militia, being necessary to the security of a free State, the right of the people to keep and bear Arms, shall not be infringed."

"Before you argue with someone, ask yourself, is that person even mentally mature enough to grasp the concept of different perspectives? Because if not, there’s absolutely no point."

– Amber Veal

"The Highest form of ignorance is when your reject something you don't know anything about".

- Wayne Dyer

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |