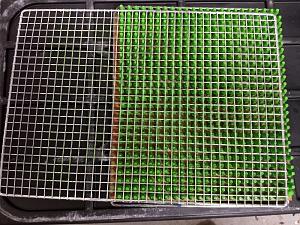

For Gas Checks I drilled/reamed some scrap sheetmetal with holes the size of the gas check shank. The holes keep the bullets upright and in place while being sprayed and protect the shank from the powder. Once sprayed I transfer the bullets to my silicone covered cooking mats. The only difference from this old photo is I now use SS cooling racks to help hold the bullets upright while being transferred to the oven. If your spraying conditions are clean the powder overspray can be swept up with a paint brush and reused.I only have two calibers, 30 & 7 mm that require gas checks. After I seat the checks I do a second coat using shake & bake coat of clear, which increased the PC thickness and bonds the check into a one piece bullet.

|

|

|

Reply With Quote

Reply With Quote