|

|

|

Very cool. Looking forward to how ti works out. Welcome to the forum.

Watching this one.

Experimental ("EXP") BHN tester. Initial test results.

15 sample ingots were used, and two people used the instruments to create the data.

Testing revealed excellent repeatability from the EXP - in more than 90% of the tests, each person's result varied less than 2% from the other. When the same person repeated the measurement on the same sample, but a different spot on the ingot surface, the value rarely differed by 2%. This is believed to be due to the accuracy the dial indicator provides, both in initial pressure, and indentation pressure. A dwell time of about 4 seconds was used. The data is a function of pressure and the nature, shape, and hardness of the specific indenter, which was a 90 degree point of carbon steel.

The main difficulty was obtaining lead samples with known BHN hardness. A precision tester designed for steel lacked the low range required for lead.

The only method available was to use a traditional LBT tester to create samples with a measured BHN value. My neighbor happened to have one. 2 measurements per person were done using blind recording to avoid bias. The average the four values for each sample was used. This process is believed to be the primary source of error because of poor LBT repeatability. The unit used required applying pressure to align two marks, and the width of the marks was about 7% of the required movement. In 11 of the sample pieces, there was plus or minus 15% to 30% variance between each dataset of four values. For the remaining 4 samples the variance was less than +- 15%.

With this much statistical noise, the only thing to be done was to use the average of the 4 values obtained for each piece. This was done for 15 different pieces. With a much larger test count, accuracy would improve.

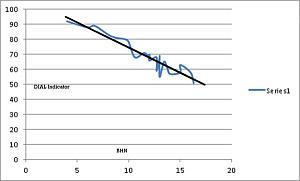

The average LBT BHN values were graphed against the EXP values - note that the EXP values are inverted - larger value for softer lead.

A line was drawn through the middle of the data, representing the best approximation of calibration. This appears accurate enough for my purposes. If I can obtain more precise lead samples, I can improve the precision.

Last edited by trebleplink; 09-25-2020 at 04:38 PM. Reason: typo

I've been using the Brinell Method of measuring BHN. What he did was press a ball bearing into a material, and measure the diameter of the indent. His scale is based on a mathematical calculation derived from this. I used a drill press, 1/4" ball bearing attached to a shaft and a bathroom scale. I measure the diameter with a micrometer, with lots of light and magnification. I've gotten repeatable results down to about 0.5 BHN.

Thanks! I hadn't seen that.

PBaholic, I have heard of using a bathroom scale for test hardness. It does work.

Thi is the principle the Lee uses. Press a 5/32" diameter ball into the lead with a 60 lbs. of force and measure the indent to determine BHN.

Using the larger ball diameter should make measuring the indent a bit easier.

On calibrating this home made tester a person could get alloys of known hardness from a seller of alloys such as RotoMetals.

I have the Lee and find it works well if you can get the hang of using the microspore that comes with it.

I have found it works well when testing on ingots as well as boolits.

Leo

Just a followup on the tester - Using PBaholic's ball bearing method of measuring samples, I was able to produce another batch of known hardness ingots and used them to calibrate the tester. It really works well, and is very repeatable. I used the LBT as a model and improved it using the Dial indicator - this makes the initial pressure and the indent pressure very precise. The dial indicator is about $17 from Shars or Ebay.

If anybody wants to make one, I might be persuaded to cut some more top plates.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |