Wow....just reading this thread confirms what I already knew...that is how much I don't know.

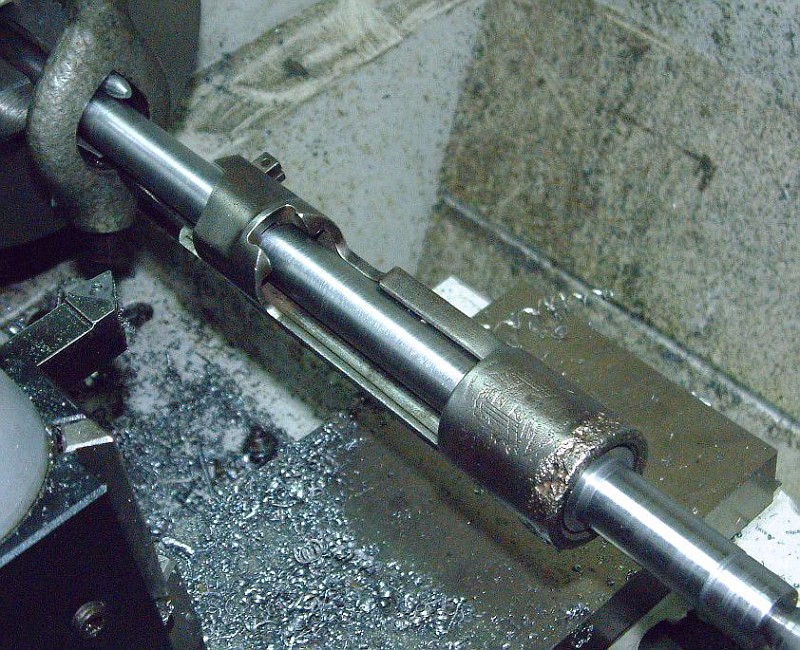

I bought a 9 X 19 Grizzly, with stand from an acquaintance worth the money to me. 90% of what I do on it has more to do with working on brass cases than anything else and, it works fine for that. The few projects I do in steel are both small and not very complicated so I just go slow. If any of you guys ever watched me work I'm 100% confident I would provide comic relief.....

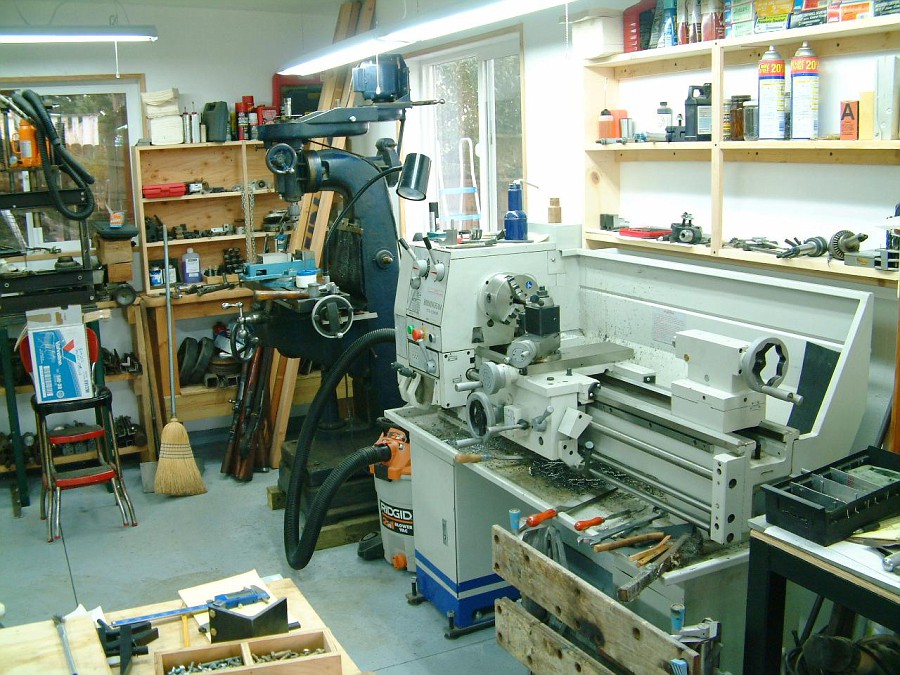

My "in house" basement shop is about 1100 sq. ft. and I'm very grateful. About 2 years after we built the house I went up the hill about 50 yards and built me a 24 X 20 shop that houses my automotive stuff and, believe it or not, 3 MG's, a '55 TF, a '56 A and a '74 B. 'Course I have to back one out to work on anything but there's a plan to add 12 more feet to the back. Then I QUIT!!!

|

|

|

Reply With Quote

Reply With Quote