Hello nueces5

What did you do to solve to problem?

THANK YOU

Mike

|

|

|

Hello nueces5

What did you do to solve to problem?

THANK YOU

Mike

NRA Benefactor 2004USAF RET 1971-95

what lead are you using? lead too soft in 9MM will cause leading.

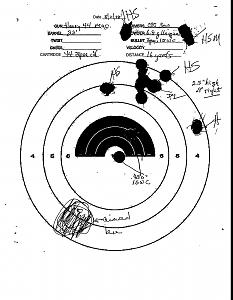

Actually I have been there with keyholing at 15 yards with a .001" - .002" difference. It was 44 Special loads in a Henry Big Boy. I was shooting Speer .430" swaged 240 grain swc's, and HSM Cowboy factory loads running about .429" and the HSM loads sure did keyhole. I then later switched to Oregon Trail .431" hard cast 240 grain swc's and all of a sudden they were even more accurate and did not keyhole. But between the Speer .430 and the HSM .429" there was an obvious difference.

Britons shall never be slaves.

the way to take

hello good afternoon friends, I greet you another from Argentina.

I wanted to share with you that I have solved the keyhole problem I had with the bersa bp9cc.

using a mold reads 105-358- swc resized to .357, Thank you all very much for your advice

hola buenas tardes amigos, os saludo a otro de argentina.

Quería compartir con ustedes que he resuelto el problema de ojo de cerradura que tenía con la bersa bp9cc.

usando un molde lee 105-358- swc redimensionado a .357, Muchas gracias a todos por su consejo

Glad you got it worked out

just a summary

The 2 biggest 9MM problems

The 2 biggest problems/causes of failure with loading cast in 9MM are OVER-CRIMPING & downsizing the boolit when seating.

The 9MM has a tapered case.

Crimping, I use the Lee FCD and only crimp to where the boolit won't move when the cartridge is pushed against a hard object.

For seating I like the NOE neck sizing dies so much I talked with a member ob CB who made a Lee powder through die with the NOE profile of several different diameters. I've had good luck expanding the brass using the same diameter expanding plug as the boolit diameter (brass springs back .001 after expanding and that.

.001 does the job holding the boolit in place!

A 38spcl/357mag expander plug should work also

I used to expand the neck with the NOE neck sizing die the use the Lee powder through setup to charge the case.

Ues a kinetic boolit puller and make sure you're not downsizing the boolit in either of these operations.

this will go a long way toward tightening up your groups and preventing leading/tumbling

I've found that barrels with shallower grooves prefer harder alloy. COWW, PC'd, quenched, sized .358 solves a lot of problems

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |