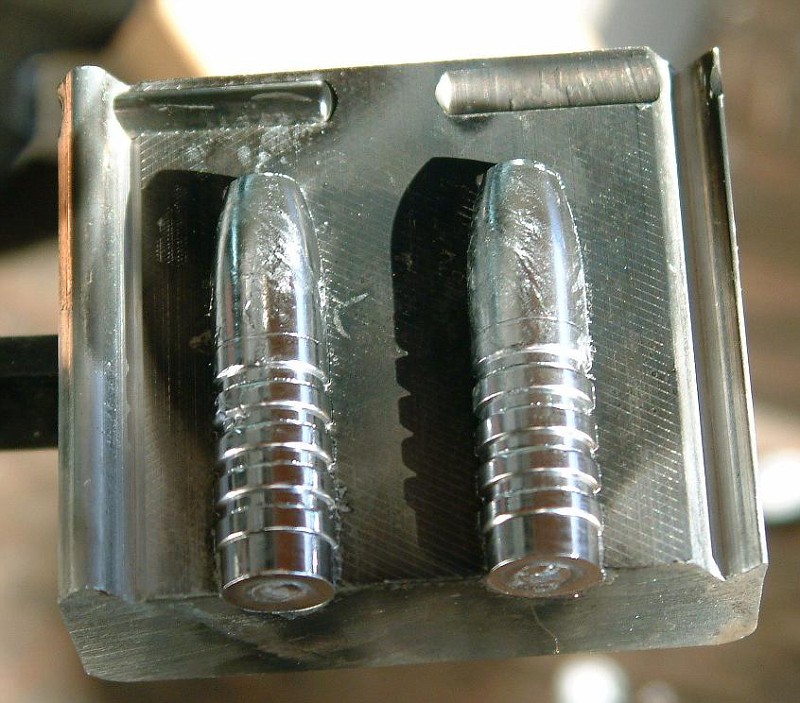

This is a Lee two cavity 8mmMax custom mold from Midsouth (not to bash Midsouth as they are my favorite supplier.)

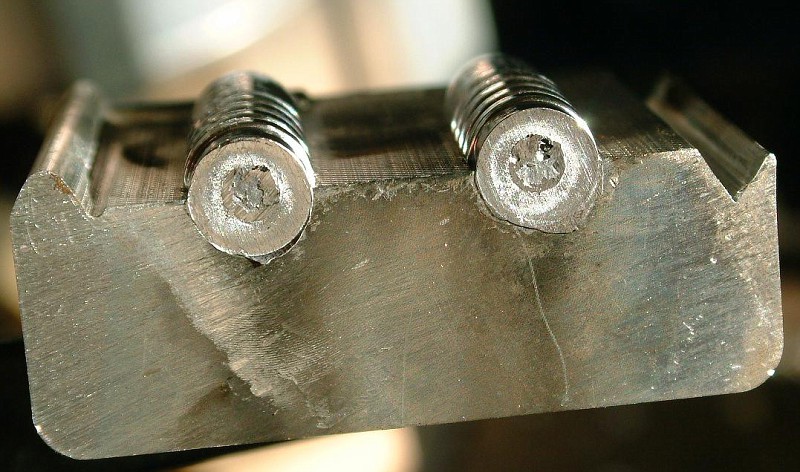

In casting with it the bottoms of the bullets were flanged. It was very annoying. In closely inspecting the mold blocks it became obvious that the mold blocks were not square with each other. This is just poor QC in the manufacturing process.

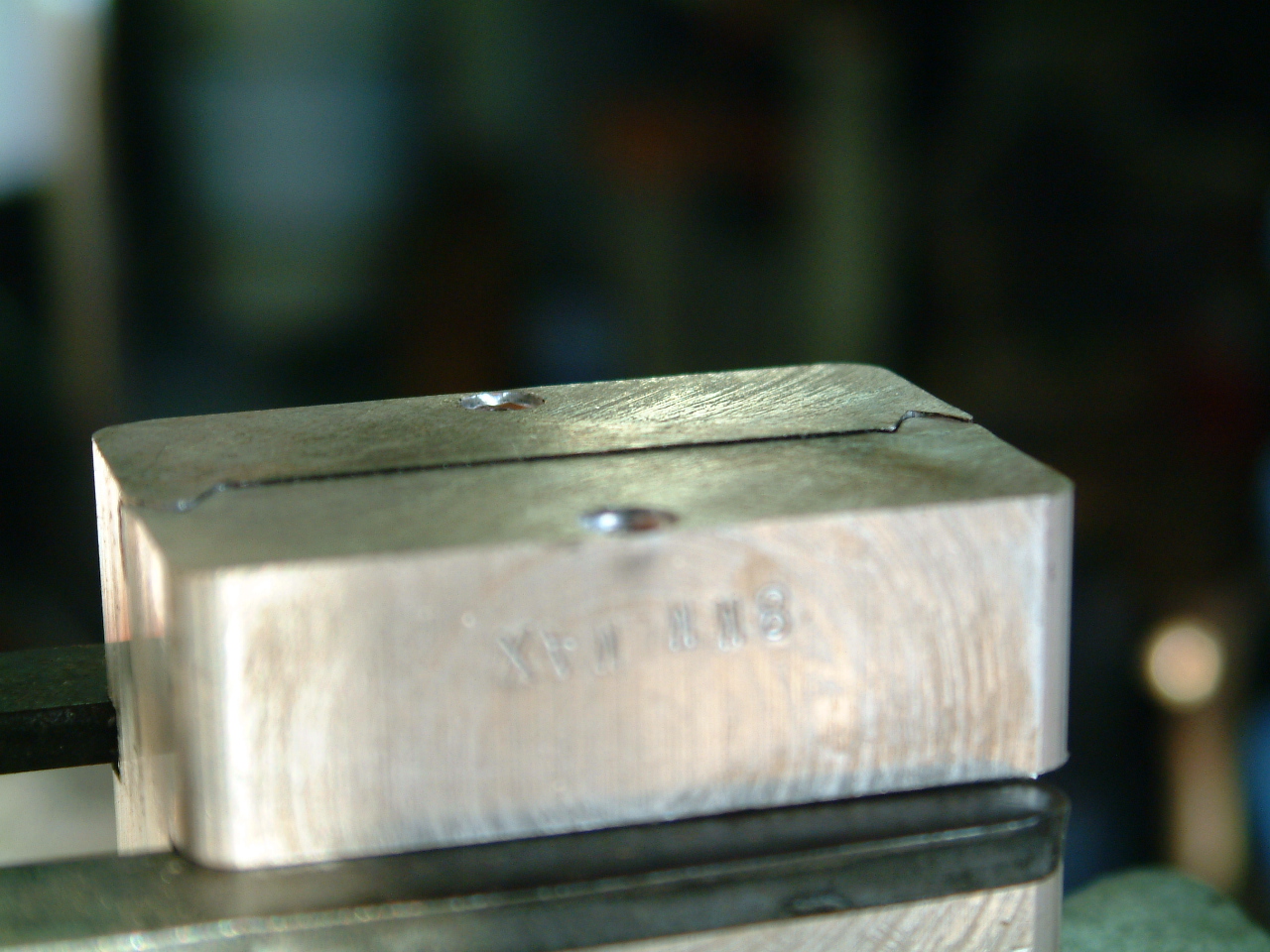

In perusing a solution to this earth-shattering dilemma it occurred to me that I could take a light fly-cut with the vertical milling machine until the blocks were flat with each other. I'm pretty sure there's enough heel on the bullet to insure the gas check room to crimp. I'll have to give that some more thought.

As I wanted a heavy 8mm slug for the 8x57 Mauser I bought a 4 cavity NOE mold approximating the Lyman 323471.

Not to bash Lee as I have several other Lee molds that drop beautiful perfect bullets. This must be the 45 caliber 250 gr mold. Drops perfect bullets, excellent quality. I shoot these in my S&W Brazilian revolver .45 AutoRim.

|

|

|

Reply With Quote

Reply With Quote