Check this out...

{ If nothing else, Check out the video below , or use this link to skip to it... https://youtu.be/aSsUYSd0k1Q }

From Brass Fetcher Ballistic Testing ( Source link is at the end of the article/page)

--------------------------------

Cold Weather Effect on 1911 Reliability

Introduction

In the interest of helping those who live in Arctic and Subarctic climates choose climate-appropriate lubricant for their self-defense and hunting firearms, we temperature conditioned a Remington R1 1911 down to -65°F while lubricated with one of four popular firearm lubricants. The Remington R1 (save being a ‘series 80’ configuration 1911) was chosen because of its dimensional similarities to the widely-available 1911 handgun. Low temperatures tend to cause oil to thicken and lose some of its lubricating properties. The temperature point of -65°F was chosen as it represents the reasonable worst-case scenario for the coldest locations on earth and is the low temperature specified in NATO STANAG 4090 (Edition 2).

Ammunition performance also changes drastically in the face of extreme cold. Depending on the primer and the nitroglycerine content of the propellant used, chamber pressures can either drop or spike dangerously above SAAMI pressure limits. We went with the SIG Sauer 45 Auto V-Crown 200gr JHP load (E45AP1) after pressure testing many different manufacturers ammunition at -65°F on SAAMI conformal pressure equipment and finding that the SIG load offered the lowest pressure drop among the cartridges tested. In order to establish our baseline, the test firearm was cleaned in an ultrasonic cleaner for 30 minutes and then heavily lubricated with the lubricant to be tested. The firearm was then shot with a fully-loaded magazine (7 cartridges) until the last shot was fired. This sequence of events was captured on slow motion video using a Phantom 711 high speed video camera.

In evaluating a bivariate system (in this case the extreme cold effect on both the ammunition and the firearm/lubricant) it is essential to first evaluate the effect of each factor independently to determine their influence on the system results. Accordingly, after the test 1911 was shot in the clean/70°F temperature condition with Remington Rem Oil, it was ultrasonically cleaned, lubricated with Remington Rem Oil and shot at room temperature with SIG Sauer 45 Auto V-Crown 200gr JHP that had been temperature conditioned to -65°F.

Performance in the context of this test is defined by the time required for the firearm to fully move the slide rearward and the time required for the firearm to fully move the slide forward. This time was measured by slow motion videography and the HSV cameras internal clock. The firearm and ammunition were conditioned for a minimum of 1 hour at -65°F prior to shooting. Both ammunition and gun were returned to a Thermotron temperature cell in the range after each shot and the temperature inside the unit allowed to return to -65°F before gun and ammunition were returned to firing position to continue testing.

Results:

Reliability

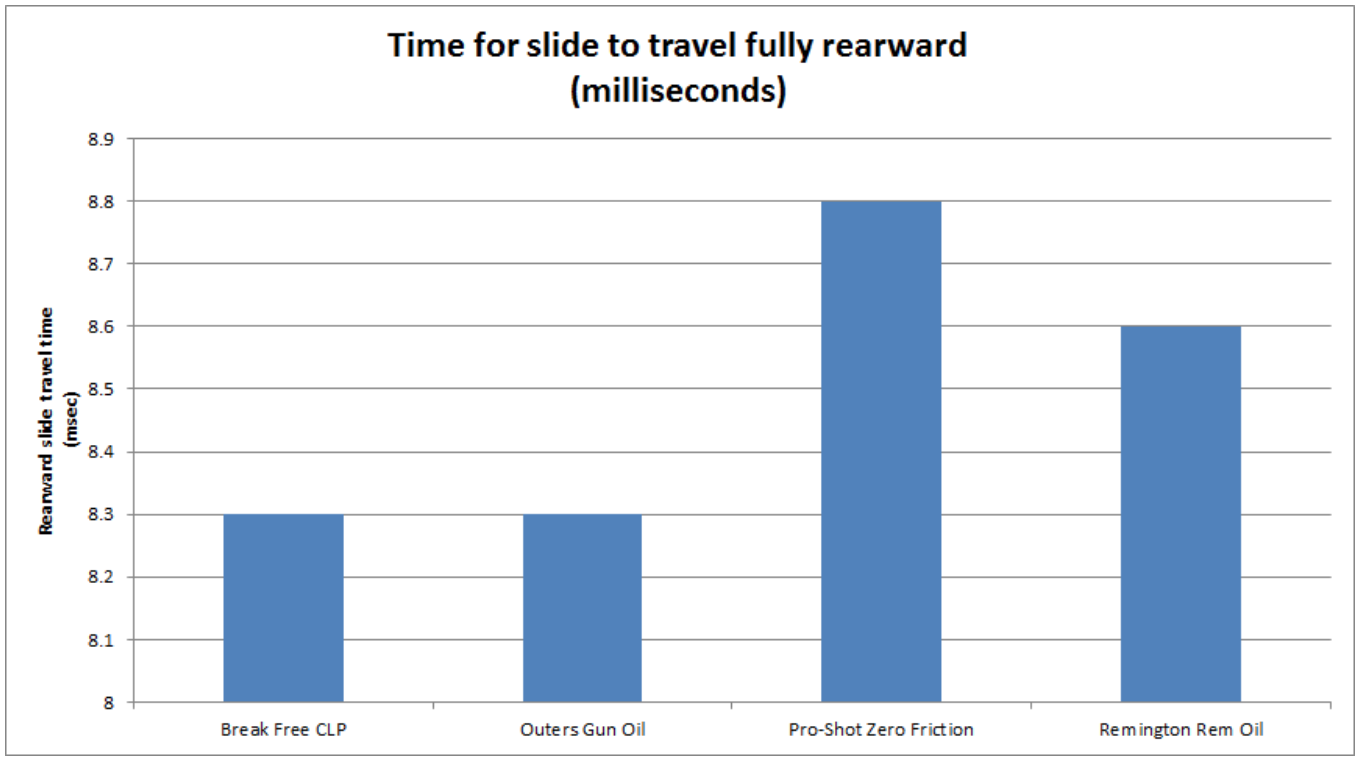

Figure 1. Time for slide to travel fully rearward (70°F Gun and Ammunition)

We see only slight variation between the lubricating performances of all four tested lubricants as the slide of the 1911 moves rearward.

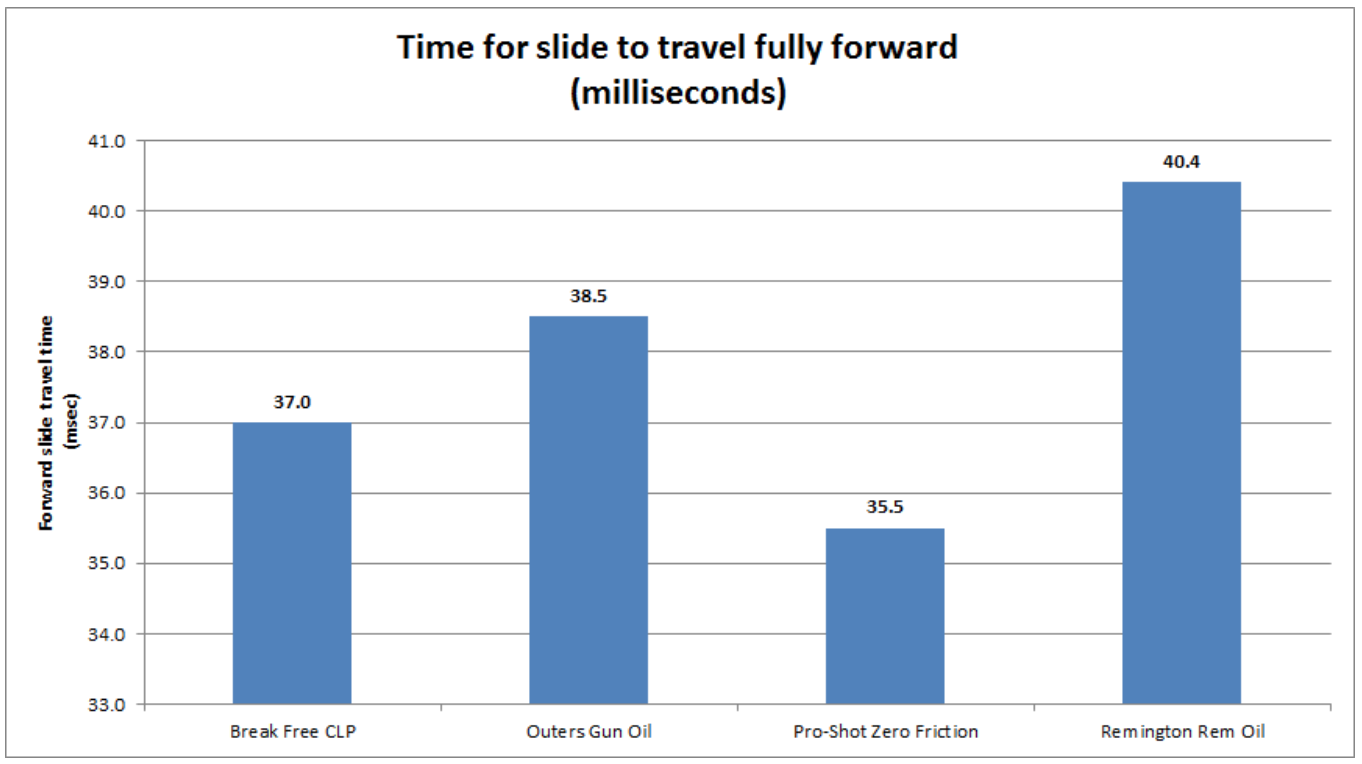

Figure 2. Time for slide to travel fully forward (70°F Gun and Ammunition)

A greater degree of variation between lubricant performance is seen here but this can be partially explained by the greater degree of complexity of motion (cartridge case bearing on magazine lips, bullet friction with feed ramp and cartridge base interacting with the extractor claw) involved with this event.

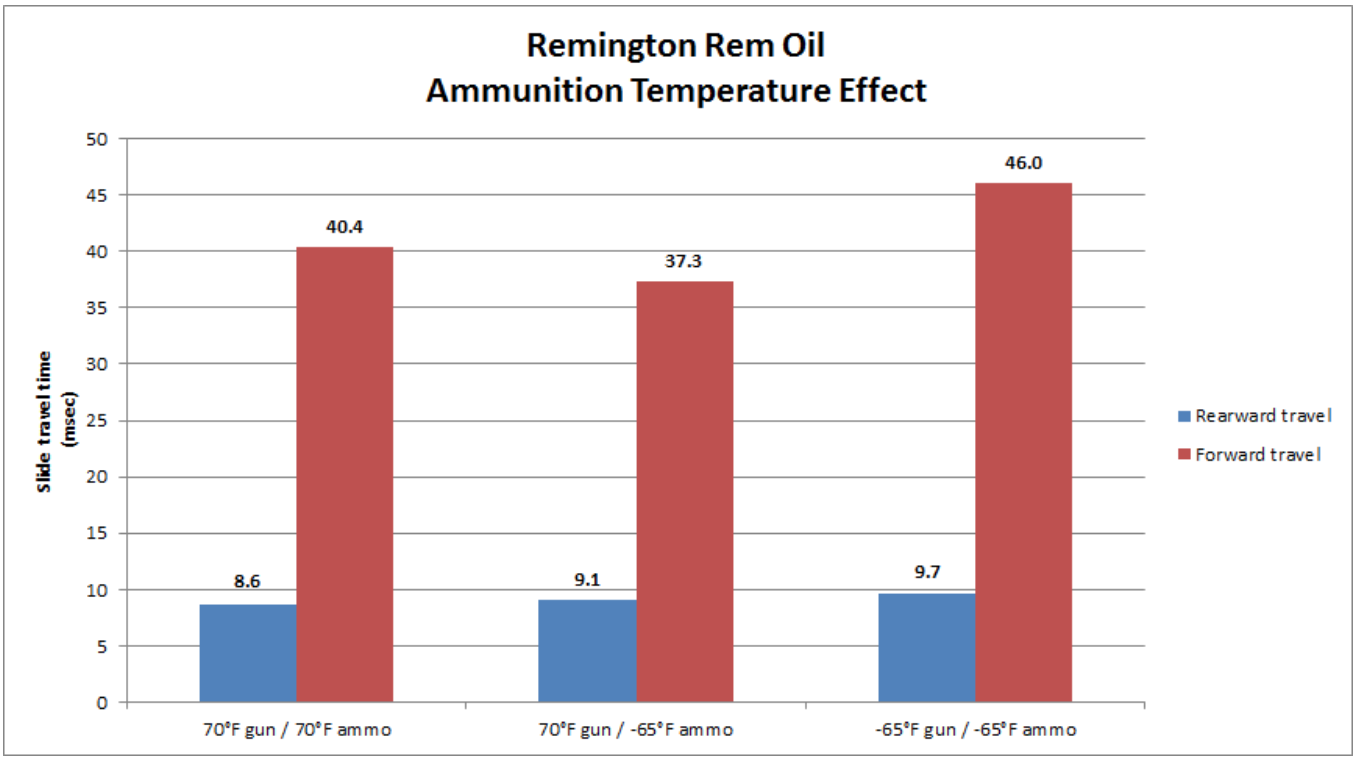

As mentioned above, this evaluation involves two variables: the effect of the cold temperature on the firearm/lubricant and the effect of the cold temperature on the ammunition. In order to isolate variables and provide the reader with a better framework within which to interpret these results, the 1911 was cleaned and heavily lubricated with Remington Rem Oil and kept at 70°F. The test ammunition was conditioned to -65°F for two hours in order to evaluate the effect of the cold temperature on the chamber pressure and commensurate rearward bolt thrust of the test ammunition.

Figure 3. Reduction in rearward bolt thrust with conditioned ammunition

There was a 5% increase in the time required for the 1911 slide to move fully rearward when the ammunition was conditioned to -65°F. This moderate reduction in chamber pressure is far favorable to a drastic spike in chamber pressure, which is common to propellant used in some defensive JHP ammunition. An interesting occurrence was the decrease in time required for the cold ammunition to chamber in the room temperature firearm. The casemouth diameter, rim diameter and overall length of (20) specimens of ammunition from the same ammunition lot were measured at 70°F and again at -65°F after a conditioning period of 1 hour. Any dimensional difference between cold-conditioned and ambient ammunition in this case is insignificant and lost in the statistical wash as can be seen in Table 1.

The coefficient of dynamic friction is known to change with different materials at different temperatures. It is possible that the extreme cold condition increased the lubricity of the nickel plating of the tested ammunition and reduced the frictional force when the cartridge came into contact with the feed ramp and breech face/extractor claw, thus decreasing the time needed to chamber a cartridge.

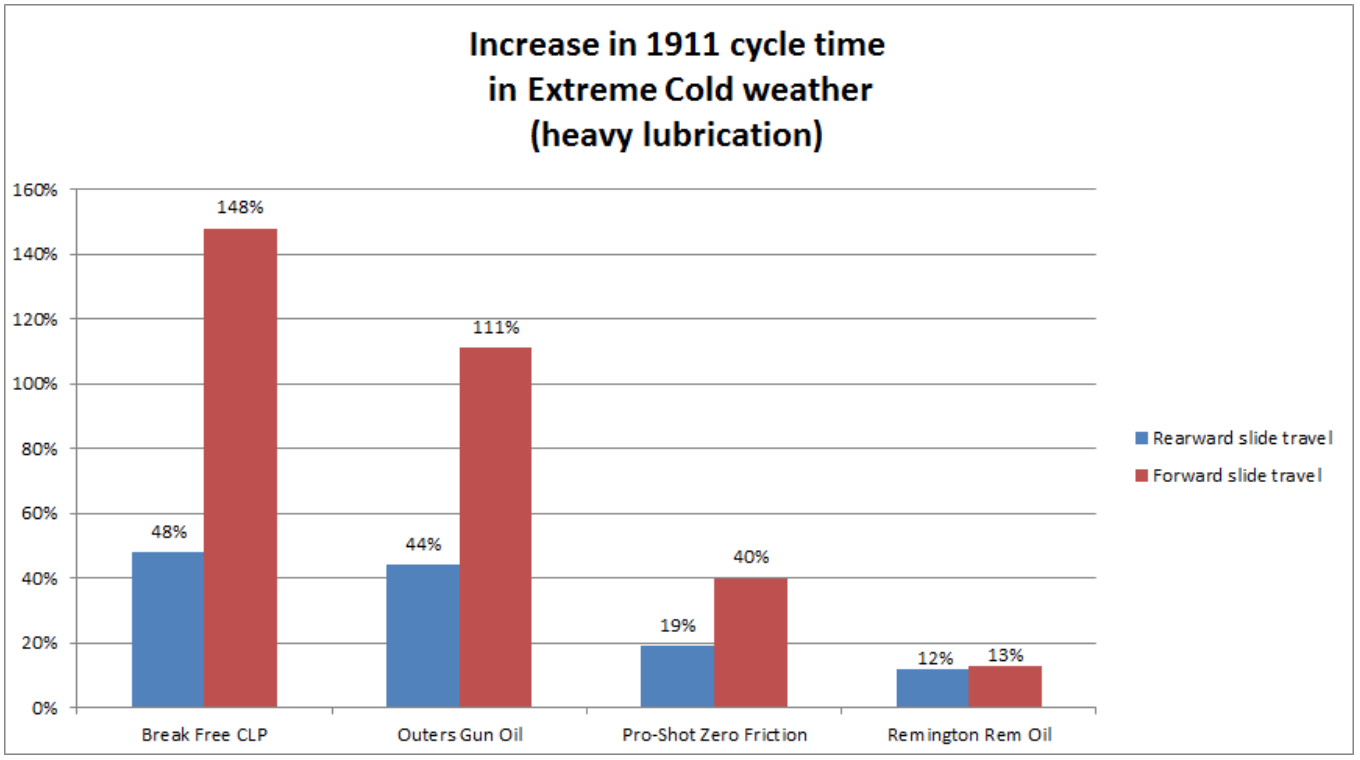

Figure 4. Increase in cyclic time with conditioned gun and ammunition

It can be seen that Pro-Shot Zero Friction and Remington Rem Oil were the least effected by the extreme cold and that Break Free CLP and Outers Gun Oil were the most effected. The subsequent reductions in reliability can be seen in Figure 5 below.

Figure 5. Percent reliability of system at -65°F and 70°F

Of the (7) cartridges tested, the gun was able to fully cycle 100% of the time with the Remington Rem Oil and the Pro-Shot Zero Friction. While slide function was significantly slowed when all of the lubricants were in use, the slide failed to fully return to battery more frequently when lubricated with the Outers Gun Oil and Break Free CLP.

Lock Time and Accuracy Effect

Lock time is the time that elapses between the release of the hammer/striker (upon trigger pull) and the initiation of the primer by the firing pin. Understanding that the muzzle of a firearm held by a shooter is always moving through a ‘wobble zone’, it is desirable to reduce the lock time of a firearm as much as possible so as to minimize the difference between point of aim and point of impact. Having to defend oneself in extreme cold conditions presents challenges to performance not normally present during normal climatic conditions. The body enhances functions generally useful for survival and decreases less useful functions during a life-threatening situation. It is generally held that hit probability with a firearm decreases substantially during combat due to this stress. Reducing lock time is a desirable hardware solution that will reduce the deleterious effect of stress on hit probability.

Tables 2A and B show the 1911's lock time using the least-affected lubricant and the most-affected lubricants: Remington Rem Oil and Break Free CLP respectively.

There exists a 3% reduction in lock time at room temperature with CLP and a 10% increase in lock time with CLP at the -65°F condition.

Mechanical Tolerances of Tested R1 Pistol versus 1911 Specifications

As noted earlier, it was desired during the planning phase of the test to select a firearm that is monetarily accessible to the largest number of shooters and that was representative of a combat handgun in worldwide circulation. The 1911 fits this requirement. A new-condition firearm was sought to eliminate any issues of excessive wear that might skew results. As such, a new Remington R1 was purchased for this test. Table 3 details the key dimensionals of the R1 at the end of the test series.

Table 3: 1911 Dimensions

Off-hand Shooting and -25°F Alternative Testing

It was desirable to evaluate whether the shooting of the test firearm from a Ransom rest provided reliability results that were not achievable by a human hand and shooter. We also sought to provide evidence of the skewing of the results due to the heavy-lubricated state of the firearm as it was initially tested (and recorded on high speed video). As such, the tested 1911 was lightly lubricated (per the users manual) with the tested lubricants and the -65°F system was shot by hand with the Pro-Shot Zero Friction and Remington Rem Oil an additional 29 cartridges each. This test was tried with the Outers Gun Oil but slow slide velocity and a continued lack of reliability prompted a halt to the testing at -65°F condition. The gun and ammunition were then conditioned to -25°F for one hour and the remaining ammunition of the tested lot was expended testing the firearm/lubricant system at this temperature, as illustrated in Table 4 below:

Table 4: Off-hand Shooting, Light Lubrication and -25°F Condition

When lubricated with Outers Gun Oil at -65°F, the slide of the weapon had to be driven into battery by hand prior to each shot. When warmed to -25°F, the first three cartridges dove into the feed ramp due to insufficient slide velocity – all subsequent shots cycled but the slide action was decreasingly sluggish as the weapon warmed.

Conclusion

Significant differences in firearm reliability can be encountered with different brands of firearms lubricant. A full-size 1911 was utilized for this test as it is considered to be a conventional semi-automatic handgun design with a successful track record in combat across 6 continents. Exposure to -65°F cold affected both the feed/function of the firearm as well as the lock time which is essential to accuracy. The two top performers, as tested, were Remington Rem Oil and Pro-Shot Zero Friction.

It should be noted that all firearms were completely cleaned of lubricant and fouling prior to lubrication with a new test lubricant. The 1911 was then heavily lubricated on all surfaces except the bore and magazine to exacerbate any differences that may arise between lubricants. In practice, it is wise to only lightly lubricate the wear areas and points of rotation (hammer axis pin for example.) Practically speaking though, one cannot dictate the condition their gun will be in at the time of a shooting – especially in the case of a ‘found gun’ whose previous owner is no longer available to shoot the firearm. It would be wise to consider that your gun might not shoot at all or will function erratically at extreme cold conditions and to plan immediate actions to correct the problem. All failures to feed involved failures of the slide to go fully forward into battery, caused by a lack of slide velocity. Extreme weather and environmental fouling of a firearm generally cause a change to the function and safety of a firearm. Some parts are free to move while others do not properly engage or work at all. In all cases, it is essential that you think for yourself and test your equipment before you depend on it with your life.

----------------------

Source: http://www.brassfetcher.com/Cold%20W...er%201911.html

|

|

|

Reply With Quote

Reply With Quote