|

|

|

Hey beetmagnet, what bullet feeder are you using?

You can get one here: https://www.doublealpha.biz/us/mr-bulletfeeder

And this way the money goes to the folks who's intellectual property was being stolen by the 3d printing of an almost exact replica of their product. It also looks like their price has come down. I recall paying more for mine. Guessing this is also in response to competing with the printers.

I recently had a motor start to go bad on mine and I had to jump thru all kinds of hoops to prove I have a genuine feeder and then had to jump through some more special ordering hoops just to get a replacement. The whole knock-off bullet feeder thing, and DA's fight against it, has really stirred up a big mess for everyone.

Karl is still making bullet feeders. They no longer have the ramp that flips the bullet. They now have 2 drops. One for nose up and the other for nose down. There are 2 tubes that come with it. You hook up the tube you want to feed the press then insert the other into something to catch the other bullets.

I just got mine yesterday. But he is not taking orders till he catches up on orders.

Double Alpha did not come up with these bullet feeders. They just happened to copyright the bullet flipper ramp.

^ can you explain ‘2 drops’ ? I was going to order one for sizing and likely loading but will need the bullets to be tip up for loading and tip down for sizing.

Hi psychbiker,

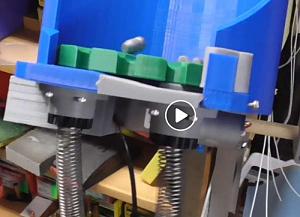

As you can see in the picture below (screencap from video,) there are two drop tubes. The one on the right is point down, the left is for base down. Since Karl has to honor the patent and not use the flipper ramp, this is the next best solution. As Tomme_boy said above, you hook up whichever tube/spring you need for your application. The other you direct into a container to catch the bullets. I have one and I definitely recommend it for the speed and efficiency in both sizing brass and bullets.

Ed

______________________________________________

Growing old is mandatory, growing up is totally optional!

Alert. anyone still looking for one of these I just seen last night that Midsouth now has the basic APP press on clearance for like $55.00

I hope I don't get in trouble for cross posting this but..... I just recently got my Lee APP press, and like it so far, but the handle was really bad. So I started looking if there were any better alternatives when I stumbled on this. Its not due out till July.

https://leeprecision.com/app-roller-...grade-kit.html

As I was looking at the image it I realized the metal arms are simply the original arms but flipped, with a roller handle in between. If you look at the original you can see what I mean.

So I checked if I could disassemble the original handle and sure enough they are two separate pieces. Once separated I had to grind down the extruded collar where it sits on the shaft on the body of the press, and then jb welded a washer (1"outside / 1/2" inside) to the opposite side. With a coat of paint, a 5" x 1/4" bolt and a nut, and a piece of dowel I had my new roller handle.

Well done... Going to do mine tomorrow. Thanks for your idea.

Hooroo.

Regards, Trevor.

Australia

Thank you! It was very easy to do. The grinding was the most challenging part, but still hard to screw up too badly. The trick is to take the nub down completely flush to the surface of the handle, without scraping up the rest of it. Really just cosmetics if you do. And paint will cover any mistakes anyway. love too see some pics when yours is done.

Was the handle on yours sharp? I was plenty happy the handle on mine. It never got uncomfortable, and is at a great angle for using when standing.

Sharp? No. uncomfortable after 500 rounds of 45 acp sizing. Yes.

I have been sizing on a Star for years with the roller handle. Am looking to make the jump to purely PC boolits and no more lubesizing, thus the APP. But having a roller handle is a bit of a requirement for me at this point.

I like Rodvan's design above, but wonder if having the handle off to the side creates any torque on the system.

I honestly think lee messed up on that plastic handle.

I had to put a rag in mine to help out.

But other then that great press.

Sent from my SM-G960U using Tapatalk

Huh. I actually don't like the handle on my Star, I wish it was just a ball end. I also was plenty happy with the APP. I did 2500 cases of various calibers in two days. Looks like a good fix if you like the roller though. It looks like all you need is an old broom handle and a long bolt, and it could be a free mod.

Hi All,

I finished the new handle mod of my Lee APP, thanks to TylerR. Rather than use a dowel, I 3D printed the handle from red PETG. The other slight tweak was my washer was a little thin, so I supplemented it with nylon washers, which should help reduce friction and hopefully extend the wear. So far, I'm liking it!

Ed

______________________________________________

Growing old is mandatory, growing up is totally optional!

I took my handles off and decided I’ll wait for the lee handle. Grinding away all the bearing area doesn’t look like a good idea. Looks like some thought was put into the lever bearing shape with the protrusion on the stamping with a smooth radius meeting the aluminum casting. The sharp corner with the grinding will damage the aluminum casting. Probably not a problem for light decamping and such. Just saying.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |