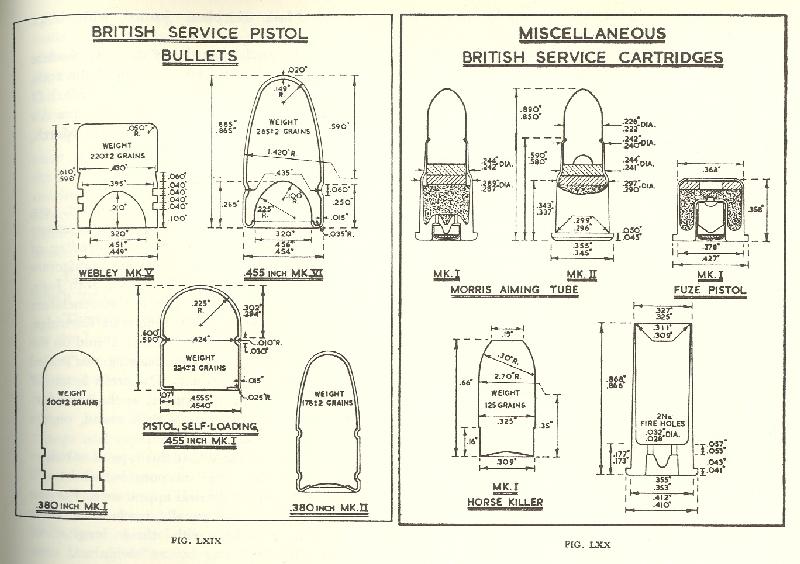

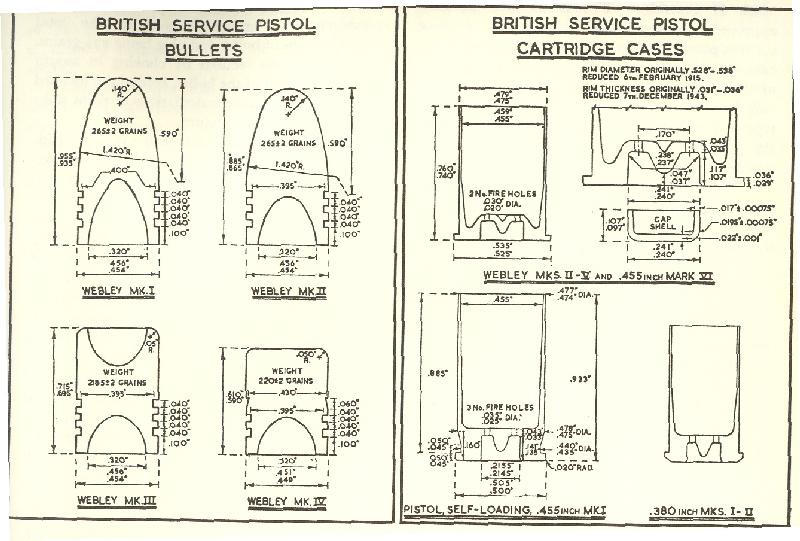

If you shoot a .455 Mk VI what is your bullet diameter?

I have fired my Mk VI some, mostly with my .45 ACP H&G 68 target loads and a few light loads with a SWC intended for .45 Colt. I thought accuracy was acceptable for an old warhorse. But I have longer for a mold for the proper .455 RN bullet.

Last week I decided to load some rounds for the beast, starting from scratch. First, to determine cylinder throat diameter for proper bullet fit. Dropped a .454" bullet into the chamber expecting it to fall right into the throat. No go! So, tried again with a .452" #68 but still no go. So I ran the .452" bullet through a .451" die. This time a snug fit in the throat. So this is the bullet size no matter what barrel groove dia is.

Is this typical for the Mk VI? If so where did the .455 come from?

|

|

|

Reply With Quote

Reply With Quote