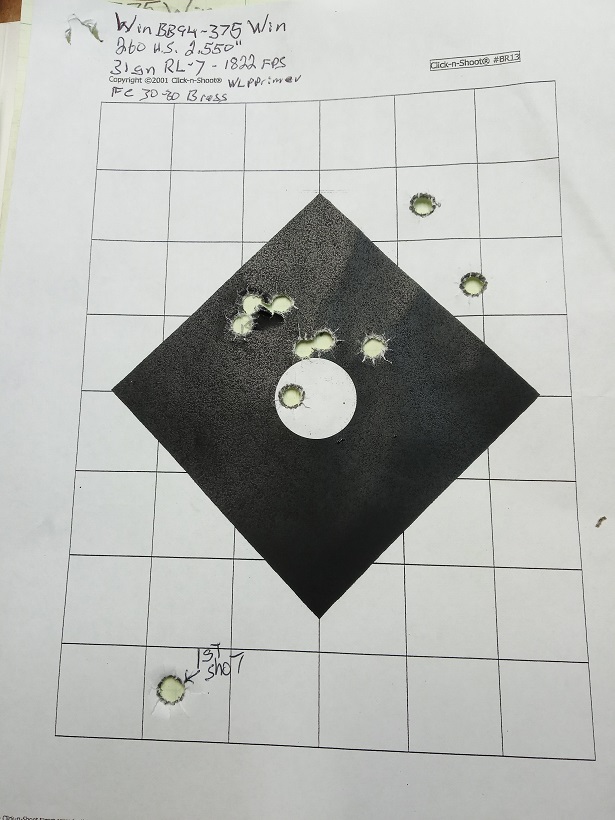

I've got a Win94 Big Bore in 375 Win that I've been trying to get some loads worked up. For Brass, I fireformed with Grits and Unique some Fed 30-30 cases, then trimmed the mouths to square them up. I have a box of Hunters Supply 260s that I loaded out to 2.550"(2.570" would cycle, so I backed it off just a little) It's still not touching the lands, but I can't really seat them out farther. I tried RL7 at 31 and 32 gns. 31gns gave 1822fps and a decent group, 32 gns went all over the place.

This was shot off the bench at 75yds with my old eyes and a Peep sight.

The first shot went way low and left. I'll have to shoot it some more and see if it consistantly puts the first shot that far out. Most of the others looked pretty good, but I did have 2 outliers to the right that I was wondering if maybe a gascheck came off or something??

Any thoughts on where to go from here?

TIA

Glenn.

|

|

|

Reply With Quote

Reply With Quote