I have been trying to make .32 RF cases at home. The firing pin barely makes it to the rim and beats up my extractor.

Is there any way to bend the tip of the pin? I tried to make it longer ( I have no idea what im doing) that didnt change anything.

They aren't light strikes either. That main spring is the stiffest one iv'e seen. I can barely cock it. I have tried Ramset cartridges but I hit way to low on the rim so they dont fire. The little winchester ones work.

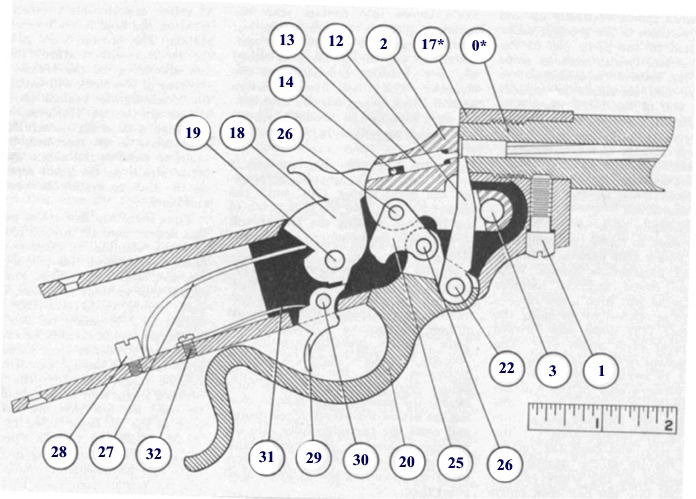

Dont worry about the rifle Its a steven's favorite. Im try stuff out on it.

Beat up extractor:

Dixie gun works .32RF case with a .22:

|

|

|

Reply With Quote

Reply With Quote