Hi, I'm copying/pasting from a thread I did last year on another forum regarding the Lee FCD in .44RM using Berry's plated 240gr FN bullets to see if anyone experienced the same or similar issues here. The issue at hand was never resolved; in the end I just reverted to crimping with the standard RCBS RC die and it works just dandy. However, having an inquisitive mind, just saying the FCD "doesn't work" is not an answer, and neither Lee tech support nor Berry's Bullets could give me an acceptable answer other than "It should work". Well, it didn't, and I'd like to know why not.

I ordered a Lee factory crimp die for my .44 magnum reloads. Turns out my RCBS dies were roll crimp dies after all, and roll crimping plated bullets is somewhat frowned upon, as there is no cannelure. Mind you, they slip right in and out of the cylinder on my Super Blackhawk with simple gravity (Sir Isaac Newton would blush), shoot and group just fine using my standard RCBS carbide dies, but my research on the interweb thingie recommended a taper crimp on plated bullets. Having experienced nothing but awesomeness out of the Lee TC dies I have for my rifle cartridges, I immediately opted for the Lee FC die in .44 spl/.44RM. Tonight's exercise in frustration involved spooling up a lot of 50 and simply seating to the correct depth without using the roll crimp function in my RCBS die. I then set up the Lee FC die and proceeded to crimp cartridge #1. Harrumph...while it did give a slight crimp, the bullet was loose. I could spin it by hand. I gave the crimp knob another quarter twist, and...hell's bells! Despite all the flowery rhetoric on the instructions (see below) Nuts if it didn't bulge the case! I backed off on the adjustment and loaded one more. It seemed OK, but looked strangely similar to the couple hundred I had roll crimped using my RCBS dies. The next three turned out like THIS:

No, you are not imagining the huge bulge in the middle of the cases.

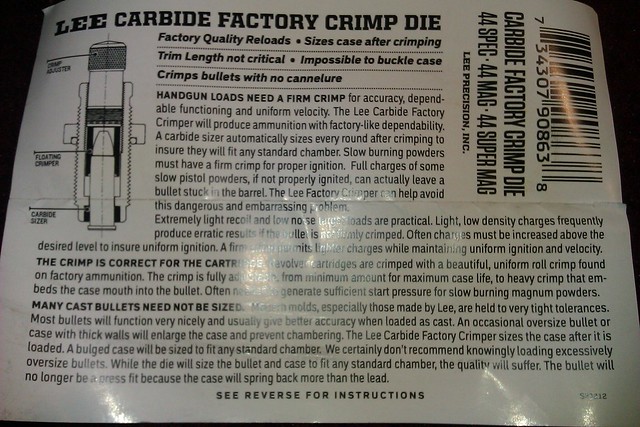

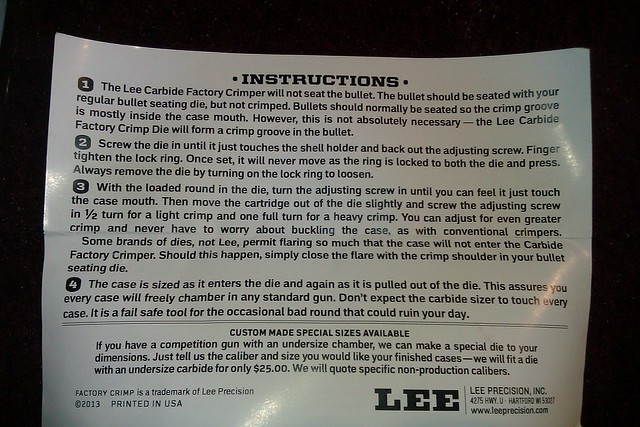

I then re-read the instructions:

Notice the fact that it is, apparently, a roll crimp die. Also notice the statements about being "impossible to buckle the case" and "crimps bullets with no cannelure"

To that, I say nonsense.

Quite frankly, the bullets I produced using the RCBS die were 100% more uniform with zero buckling or bulge. After pulling the bullets and powder and resizing the cases, I have three cases that MIGHT be able to be fire-formed and resized again, but doubtful. This die should have performed to the specifications in the instructions. Instead, it ruined three good cases. I will call Lee Precision to get their take on this before doing any negative reviews, but the Captain is NOT a happy camper.

FWIW, I stopped crimping immediately on the rest of the batch. No sense throwing good money after bad.

|

|

|

Reply With Quote

Reply With Quote