Just a suggestion...

If ya get into the habit of taking brass you bring home, on the ground or not, and put it in a container that has a lid and put a small amount of citric acid powder, a couple drops of dish detergents & with hot water about 1/2 to 2/3rds full with everything inside , put the lid on, shake for 30 secs or so. let it sit about 5-10 minutes, shake again for about 30sec - 60 sec. & then put into a colander & rinse under hot water. Then put in an old towel, or cotton T shirt like the brass is sitting in a hammock & rock it around a bit to get most of any rinse water off & set it somewhere to dry before you do anything else you will likely bes surprised at how nice the brass looks after such a little solution "bath".

IMO, you will be pleasantly surprised if you have not done this before & it is not expensive in time, nor in$$ to do it, for the results you gain. You can also de-prime first with a Lee Univ. De-capping die first, if ya choose, but that might be going overboard for some folks & just right for others. I have done both & just do what I feel like when I do it. Mostly for me, it is with the old primers in & deal with them later...

Just thought I would mention it since you did not. I can pretty much assure ya that it will help.

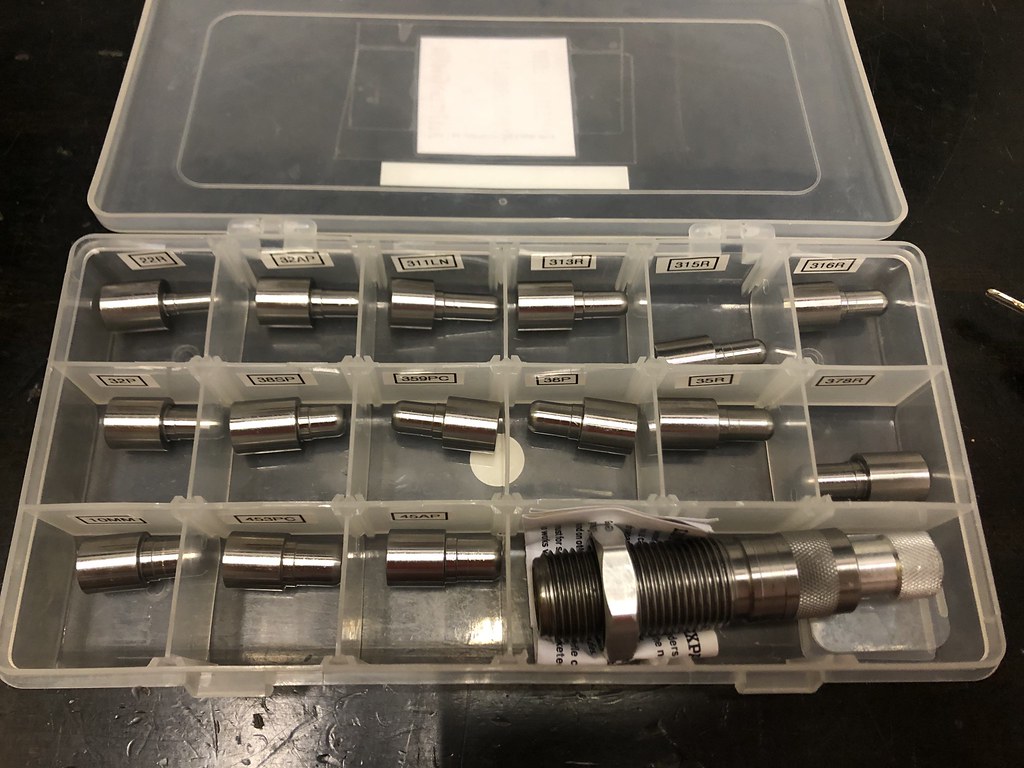

P.S. - maybe , if ya have some, try putting a very light coat of JPW on your NOE plugs & let them dry before using. That or maybe some silicone spray & let dry. Might be the "cat's meow" for ya. Something to try & doesn't cost much or take too much time.

Reply With Quote

Reply With Quote