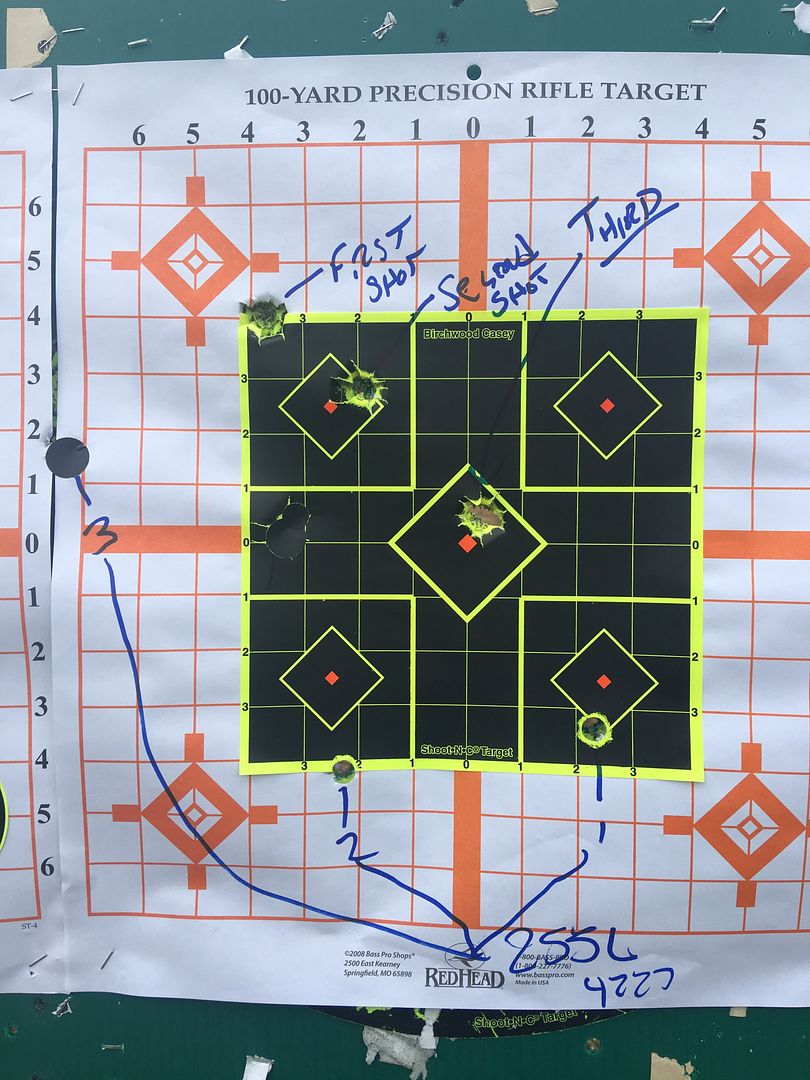

It to me is not a PC thing but needed a place to post for help. I am loading lee 300gr FN in a 450 bushmaster. I got some help the summer before last over on 450 BM.net with taper crimping for this round. I was told to taper to .474”. That’s what I’ve been doing. I did work up a load that shot a hair over MOA at a 100 yards testing it last year. I took it out the other day and would get a flier once in a while. The fliers would chrony about a 100 FPS lower. I did find out one of my scope base screws were loose which was aiding in the fliers. All of a sudden I’d have a boolit drop four plus inches and have to sight it in again. The scope was sliding back s well. I did notice that when the gun recoiled my lead sled was a little crooked so I ligned my chrony straight with it again and was getting close to the original FPS readings I started with. So it could have been the boolit path going through my chrony in a diagonal path causing the velocity variable and or my optic shifting causing fliers. But I’m still wondering if I’m taper crimping too hard since I have a shiny pd exposed ring around my boolit when I pulled it. It’s obviously cutting onto the boolit. I’m pushing these pretty good (2070fps)so I need to hold them in place.

|

|

|

Reply With Quote

Reply With Quote

DougGuy

DougGuy