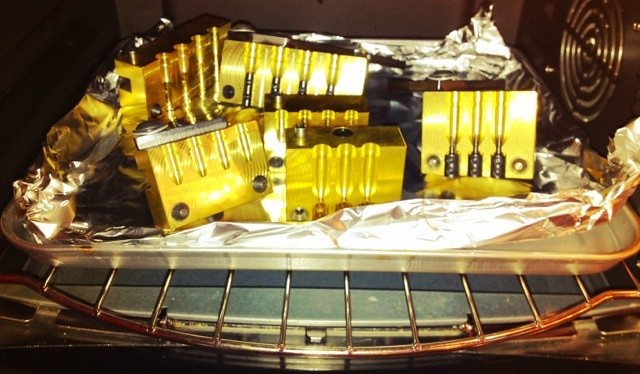

Never had a brass mold, or a HP mold that I could cast worth a darned with. Bought a new to me, and almost new 358429 brass hp. Spent most of the day conditioning it. Had to fight serious temptation to jump right to casting with it. And WOW. I like to think I'm a hard one to impress, but this has to be the best mold I've ever had. Absolutely flawless machining, and casts like a dream. Going to have to start a MP collection now. Something else to spend money on

|

|

|

Reply With Quote

Reply With Quote

Smoke4320

Smoke4320

a discussion about it, but as Beagle333 said; I did precondition brass moulds and sometimes not. Some run from the first pour, no matter preconditioning, but mostly my brass HP moulds start to really work after 3rd casting-don’t know why.

a discussion about it, but as Beagle333 said; I did precondition brass moulds and sometimes not. Some run from the first pour, no matter preconditioning, but mostly my brass HP moulds start to really work after 3rd casting-don’t know why.