I’ve noticed some issues with my reloads when the bullet is not quite concentric

Inside of the brass case. If I roll the cartridge across the table I can see movement in the bullet tip. Anyone have any tips on how to improve this?

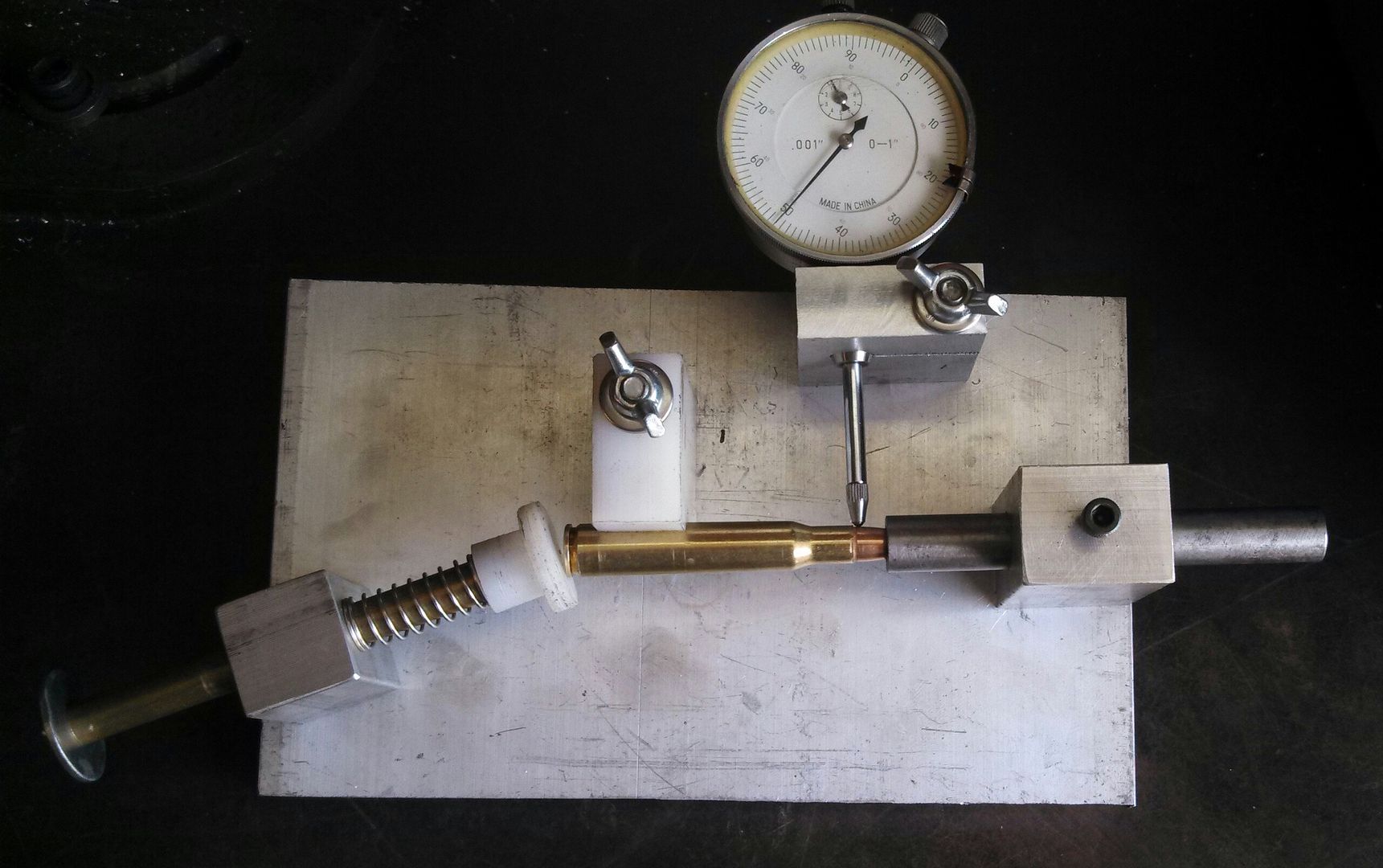

I don’t know why I put this in the picture section

|

|

|

Reply With Quote

Reply With Quote