I have 220 pounds of alloy that tests at 14.5 to 55 Brinell. It's WW mixed with lead. I need to soften it up to about 10 Brinell. How much lead do I need?

|

|

|

I have 220 pounds of alloy that tests at 14.5 to 55 Brinell. It's WW mixed with lead. I need to soften it up to about 10 Brinell. How much lead do I need?

"55 Brinell"?? Pure Antimony is only Brinell 50

I'd be re-smelting that 55 Brinell stuff to see if you can flux out the contaminate.

It all could be contaminated/alloyed with something COWW is usually in the 11 -13 BHN area

first, you need to separate the ingots by BHN (hardness)

then you need to start accumulating pure lead pure = 5 BHN but roofing lead and SOW (stick on wheel weights) are easier/cheaper to get

you then test the hardness of the pure/soft lead and mark the ingots.

you can then either use the calculator or do the math,10# 15 bhn + 10# 5 BHN + 20# 10 BHN

oops 15 brinell

I've been getting the pure lead from rotometals

Let me put this another way. I can't do math. At all. If I cant figure out how much lead to buy to melt this stuff down, I'll just have to throw it away, and just buy a bunch of new lead. This will cost me several hundred dollars, so if someone could just help me with the answer here, I would be really greatful.

Try 2:1 or 3:1 Pure to your hard if it's still to hard to your liking go 4:1

2:1 should be your ticket

Using the calculator with 220 pounds of Lyman #2 that is listed as 15 brinell added 440 pounds of pure to get 10.6 so I would agree 2:1. Although I don't know how to get to 14-15 by adding pure to wheel weights.

My range scrap comes from a 25 yard handgun range. At first I thought it would be too soft and I would have to harden it up. Since then I got a harness tester and it comes out to 16-18 BHN. Apparently, most shooting there were using hard cast boolits. I’ve been wondering if I can soften it up any other way, but adding pure lead. Much harder for me to find, without buying, than range scrap. Can antimony be heated out?

GNG,

I'll try to answer your question so that you won't need to do any math to make it work. and also show some images that may help you to understand how it works.

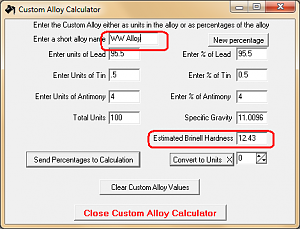

If the Brinell Hardness of your alloy is averaging about 14.75. Age hardened Wheel weights only have a Brinell Hardness number of about 12.43. Your alloy of wheel weights most probably did not have pure lead added to it. The added lead probably was a mix of lead and antimony.

Using the Precision Software Alloy Calc. Application, I created an alloy from wheel weights and then added enough antimony that brought the Brinell Hardness value up enough to match the BHN of your existing alloy.

(Click on each image to view full size)

Then your alloy was imported into the Alloy Calculator and enough pure lead was added to bring the Brinell Hardness number down to your desired value of 10.

So, if you add 17 pounds of lead to every 5 pounds of your existing alloy, the resulting age hardened BHN of the new alloy should be very close to a value of 10.

This means that, in order for you to convert your entire 220 pounds of alloy to a BHN of 10, you will need to come up with an addition 748 pounds of pure lead.

Of course you do not need to do that all at once. You just need to buy 17 pounds of pure lead for every 5 pounds of your alloy that you want to adjust to a BHN of 10.

If you have a 20 lb pot, it will only hold about 18 lb of your finished alloy. So adding 14 lb of pure lead to 4 lb of your existing alloy should get you real close.

If you only have a 10 lb pot, it will only hold around 9 lb of your finished alloy. Adding 7 lb of pure lead to 2 lb of your existing alloy should work for you.

I hope this answers your question without the need for any calculations.

If you still have questions don't hesitate to ask.

something is wrong, either your 220 lbs of alloy is WW mixed with something other than soft near-pure Lead, or your measuring tests are incorrect.

Either way, I mix my COWW (BHN=12) with soft near-pure lead at a 50-50 rate, and I get a alloy that measures around 9 BHN with the Lee tool. That alloy is a very good for 38 spl or 45 colt or other pistol calibers that are down loaded to low pressure loads similar to the 38 spl or 45 colt.

~~~~~~~~~~~~~~

“If someone has a gun and is trying to kill you, it would be reasonable to shoot back with your own gun.”

― The Dalai Lama, Seattle Times, May 2001

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |