Paper Patchers tell me how you make your patches. I like shooting my rifle and casting bullets and loading ammo but dislike the patch making process itself andI am wondering how some of you are doing it?

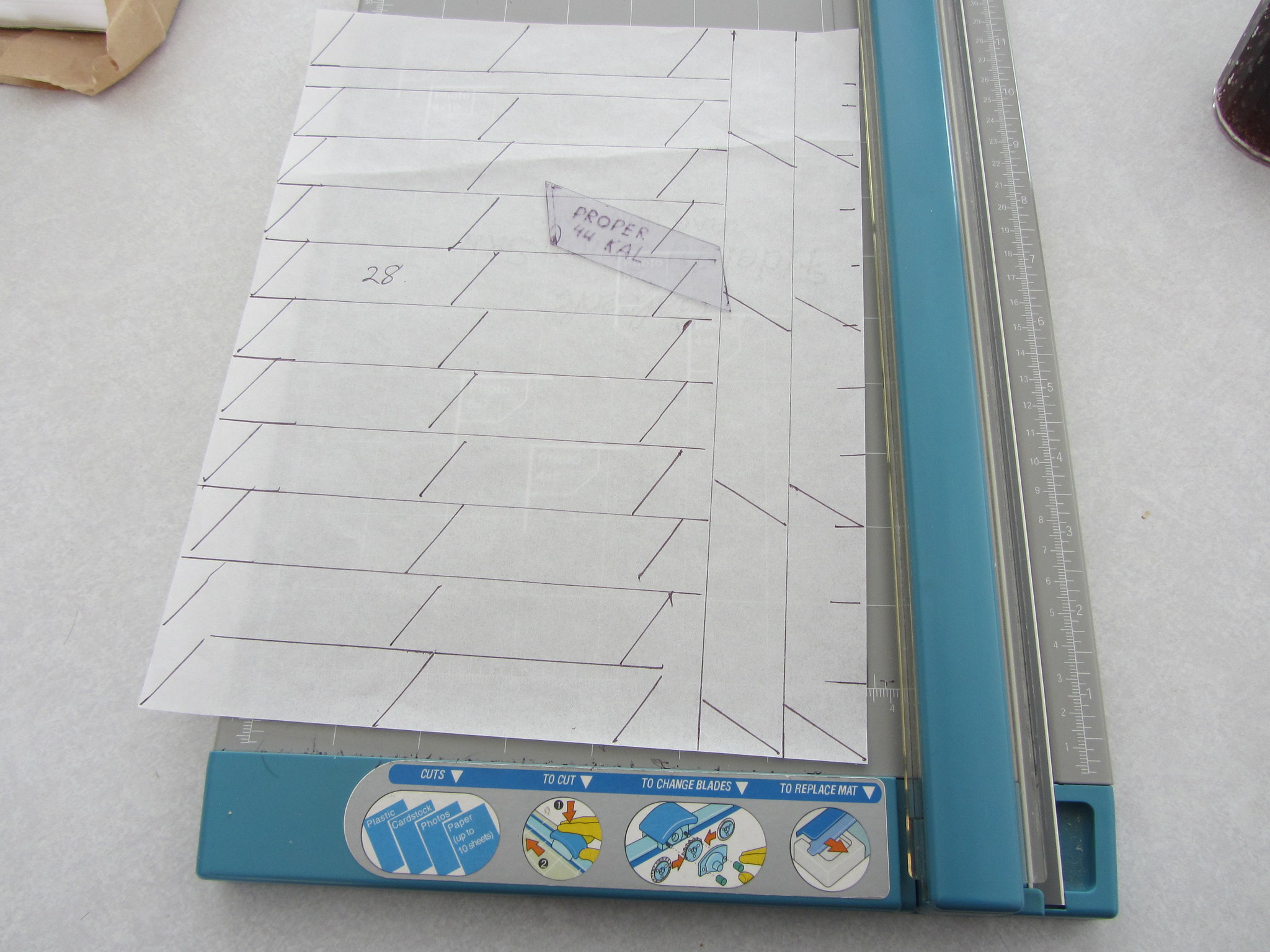

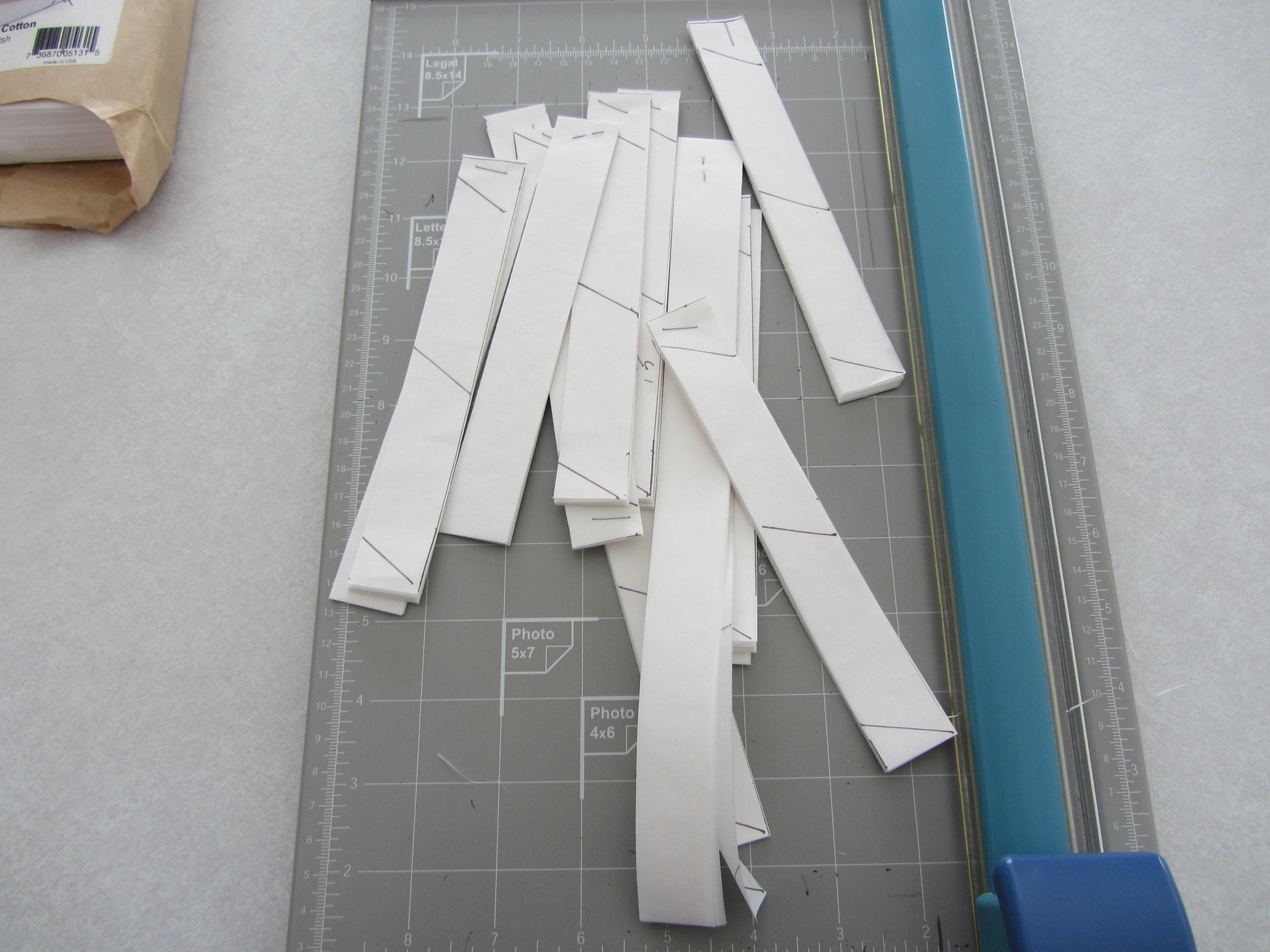

I have a paper cutter and make strips and then use a template to lay out the patch.

perhaps it seems as tedious for everyone as it does for me!

|

|

|

Reply With Quote

Reply With Quote