I am going to attempt to form 8 x 58R from 45 X90. Has any one done it and what are the steps to do it. What other dies will i need to get to 8 X58R. I have a set of 8 X 58R dies on the way and have brass on hand.

Dan

|

|

|

I am going to attempt to form 8 x 58R from 45 X90. Has any one done it and what are the steps to do it. What other dies will i need to get to 8 X58R. I have a set of 8 X 58R dies on the way and have brass on hand.

Dan

I have forming dies for several cases based on the .45-70 case.

I have never formed your Krag brass but I have formed .33 Win, .38-56 Win., and 40-65 Win from 45-70 using RCBS forming dies.

It is my estimate that your 8MM case could be formed easily with 2 or 3 intermediate forming dies before use of the 8mm DK FL die.

These 2 or 3 dies can be FL die bodies and trim dies.

Use caution buying FL dies to form the long 45-90 cases.

Short closed top FL dies like those made by Lee have the small top thread that prevent the case mouth of a long case from passing through the die body. I call those closed top dies. RCBS trim dies and some other brands of FL dies have larger top threads. These threads permit the long cases to pass through permitting easier forming

The 3 die calibers I mentioned are useful for the forming that you want to do. If you have a large assortment of FL and RCBS trim dies there are others that can be experimented with.

They include the rounds based on belted H&H magnum brass such as the long tapered 300 H&H and the .375 H&H. Other shorter dies that have large bases include the .44-40 Win. and .38-40 Win. .

It all depends on what you already own or what you can borrow or buy easily.

You can explore these choices if you have a copy of Cartridges of the World.

EDG

Thanks

The only dies that i have are 45-70, 44-40, 43 Beaumont and 8mm label that the case will fit in. 8x58R dies are on the way.

Dan

Treekiller,

I spent a lot of time and money gathering the forming dies that I own.

One other large caliber short die body that might be useful is the .350 Rem Mag.

If you need help with intermediate forming steps let me know. I would be glad to form some of your cases to permit you to finish size them to 8mm.

EDG

I have Formed these using Intermediates . this is The hit or miss method. Basically you will waste more new bass than get good ones.. anew set of Forms and Trim , I checked with CH4d appox $250 . Thats if available.

Economy wise unless you like forming . Purchase 50 new Cases and Be done with It. the final step will be to turn down the rim if necessary

NRA Endowment Member

International Ammunition Association

New York, the Empire State Where Empires were Won and Lost

Salpal

I have to disagree with the assertion that you will waste a lot of brass.

A carefully developed process takes a little time but will yield 100% (or very close to it) good cases. So says my 50 years of hand loading experience and 40 years as a manufacturing engineer. Case forming is a very easy process to perfect compared to many of the thousands of manufacturing processes I have developed for medical implants, aerospace and semiconductor components.

EDG

Thanks to all with help on forming the 8 x 58R cases. Especially to EDG for offering and forming some for me.

Thank You All

Conundrum.

Making 8x58RD brass....

I have used a digital 6" caliber to measure the rim thickness in my arsenal sporterized Gustaf Rolling Block chamber, mfg'd 1871, chambered 8x58RD.

I get 0.0695" to 0.070" for what will translate into headspace / rim thickness.

Does this mean I might have problems making brass from 45/70 Starline, which is around 0.060" headspace, rim thickness.

The only rimmed cartridge I have ever loaded was for an early forties Win 94 in 32 Win Spl. That's pretty simple. Open up some 30-30 and Bob's your uncle.

This rolling block is quite the project. It is going to cost me as much in gear to reload for it as I paid for the rifle!

thanks

You can try the trick that the .303 British guys use, to slip a small O-ring ahead of the rim to keep it tight against the breach block. You probably wouldn't need to do that, if you can seat long enough to get the bullet into the rifling. I may have to use the O-rings on my 8x56R brass, as the rim thickness is only .055.

The RCBS dies definitely do - at lease the set I used did.

There are closed top RCBS dies that will not permit forming extremely long cases.

I am pretty sure that all of CH dies are open top.

Open top means the top of the die is drilled and tapped for a bushing for the decapping rod.

That bushing hole is normally larger than the case neck being formed with CH.

RCBS varies according to when the dies were made since they changed the design several times making dies both closed top and open top in the same caliber.

EDG

Well, got the 45-90 brass from Graf's and the CH4D dies from Buffalo Arms.

Got the Lee ~200 grain 8mm mold, gas checks.

Now I need to form the brass, cast some bullets and get a sizing die.

I can't seem to get a 0.329" dental lead slug down the bore easily; it's 0.323" at the muzzle and the leade.

I've a Star Lube Sizer. Go for a 0.325" die? $50 a pop at Magma engineering, don't want to screw that up.

Don't understand why LEE makes a 0.323" sizing die? Seems sort of small to me? Next size up is 0.339". Go figure. Star/Magma it will be.

I've made about sixty passes of [pick one: carb out, Kroil, wipe out, kerosene, Ed's Red] for an hour to overnight, followed by [pick one: oversize bronze brush, nylon brush with brass scour pad stuff wrapped around, nylon brush patched with Corbin Bore Cleaner, etc.) Don't worry. I swab out with non-chlorinated brake cleaner when changing chemicals, not that any of these are likely to interact.

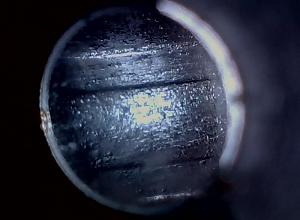

Carbon situation is getting better according to my bore scope (Teslong! Buy one! Solid tube. Amazon. ~$70.) but geez this is taking forever.

I've spent significantly north of the $325 I paid for the rifle, just for the reloading gear.

Can't wait to shoot this big dog.

If the rifle warrants it, I will be looking for a tang sight that is graduated and does not cost north of $450?

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |