and who doesnt have that problem *grins*

seems no matter how big or how many shops Ive got 10 days later its too small.

anyway I digress,

Im new here and to reloading so I dont know if this is commen practice but I found this in "Precision Handloading" by John Withers and it struck me as so dang smart and handy I had to share in case others like me are like * jeez there ya go!*

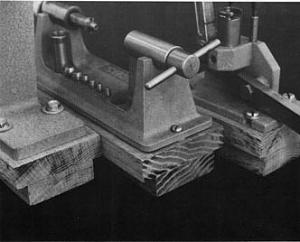

he blocks his tooling bases and uses his heavy duty bench vice to mount what he needs, when he needs it.

frikken genius

|

|

|

Reply With Quote

Reply With Quote