The 296 loads look like there is ignition problem. Where did the 2400 loads hit?

|

|

|

The 296 loads look like there is ignition problem. Where did the 2400 loads hit?

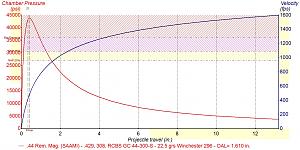

I ran the 296 load thru Quickload and it shows 44,000 psi & 1600fps. Seems a bit high for minimum starting load? It also shows this to be a compressed load at 104%. Are you using magnum primers? That much 296 is going to need a magnum primer and heavy crimp to get good ignition. As I stated previously you maybe having ignition problems?

I’m using published load data from Lyman 4th edition. The mold I have is not listed there so I substituted the Lyman 429667 bullets data. Mine is Accurate’s 43-240AG. Minimum load for the Lyman is 22.5 of H110.

Primer used are WLP’s. I do have some CCI 350’s I have not tried yet. I am pretty new to casting and if I’m approaching dangerous conditions, I certainly need to realize that.

I’ll have to compare mold specs and check case fill again.

My mistake, I used 300 gr based upon first post. I will rerun with 240 gr cast.

I didn’t even notice that. Where do I find that calculator? Would it be safe to use that using different bullet designs of same weight?

Quickload is purchased piece of software. For cast loads seating depth is more important than bullet profile...

Interesting. Im having trouble finding brass that allows me to achieve case length listed in the manual. To a accumulate any quantity I chose to trim 1.280”. I’m getting about + .007 after resizing. So when you say seating depth, are you talking about the resultant case fill percentage Or distance from rifleing?

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |