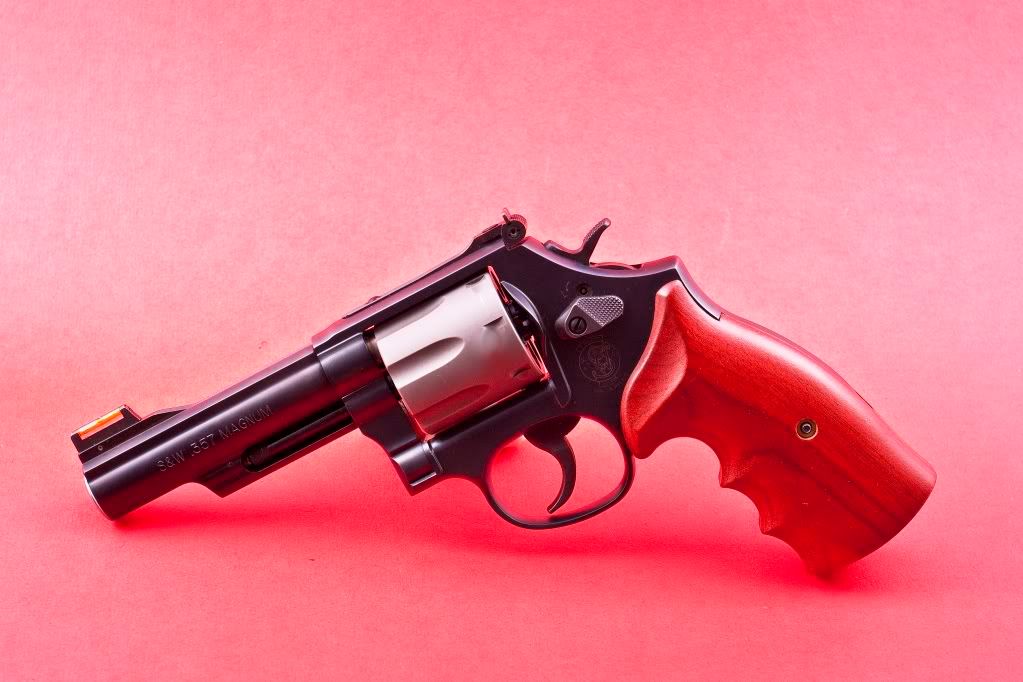

Iím thinking of getting a new Smith 686 and understand that these are manufactured with EDM rifling. What are guys doing to get good results with plain base cast bullets in these revolvers? Will JB bore paste be enough to smooth the micro burrs or is fire lapping necessary? Iíd really like to use my MP 358429 clone but if the boreís going to lead like crazy I donít want any part of that.

|

|

|

Reply With Quote

Reply With Quote