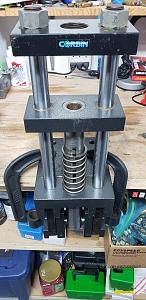

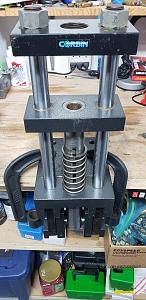

I'm looking for some help identifying what Corbin press this is. I figured it was a Corbin CSP-2, but the measurements don't match Corbin's site.

Corbin's site excerpts:

There is 15.5 inches from the top of the press to the bench on which it mounts. It is 15 inches from the bench top to the lowest point on the press itself, without the handle .The press has two stroke travels, depending on the setting of the ram pin. In the long stroke (reloading) mode, the space between the lower side of the head, and the top of the ram plate, is 9.5 inches with the ram down (A in photo) and 3.5 inches with the ram up . With the press set for the short stroke or swaging mode, dimension A is 8 inches and dimension B is 5-1/8 inches . The distance from the top of the base or mounting plate to the bottom side of the press head is 12-1/2 inches.

Space between supportsA 3.00

Width of head B 6.00

Support Diameter C 1.00

Head threads D 1.5-12

Ram threads E 1.0-12

Ram-Head top of stroke clearance, short stroke modeF 5.125

Ram-Head top of stroke clearance, long stroke modeF 3.500

Ram-Head bottom of stroke clearance, short stroke mode G 8.00

Ram-Head bottom of stroke clearance, long stroke mode G 9.50

Head thicknessI 1.00

Head depthJ 3.00

Support centersK 4.00

Mounting plate depthL 8.00

The press I received the measurements are as follows: ( Measurement to nearest 1/8")

There is 14 inches from the top of the press to the bench on which it mounts. It is 9 inches from the bench top to the lowest point on the press itself, without the handle . In the long stroke (reloading) mode, the space between the lower side of the head, and the top of the ram plate, is 8 inches with the ram down (A in photo) and 2 inches with the ram up . With the press set for the short stroke or swaging mode, dimension A is 6.5 inches and dimension B is 3.5 inches . The distance from the top of the base or mounting plate to the bottom side of the press head is 11 inches .

Space between supportsA 3.00

Width of head B 6.00

Support Diameter C 1.00

Head threads D 1.5-12

Ram threads E 1.0-12

Ram-Head top of stroke clearance, short stroke modeF 3.500

Ram-Head top of stroke clearance, long stroke modeF 2.000

Ram-Head bottom of stroke clearance, short stroke mode G 6.500

Ram-Head bottom of stroke clearance, long stroke mode G 8.00

Head thicknessI 1.00

Head depthJ 3.00

Support centersK 4.00

Mounting plate depthL 8.00

Any thoughts? I was mainly looking for a CSP-2 to swage big 50 cal projectiles for my 510 Whisper. My concern is the linkage setup seems to be different than the CSP-2, potentially affecting the leverage.

Reply With Quote

Reply With Quote