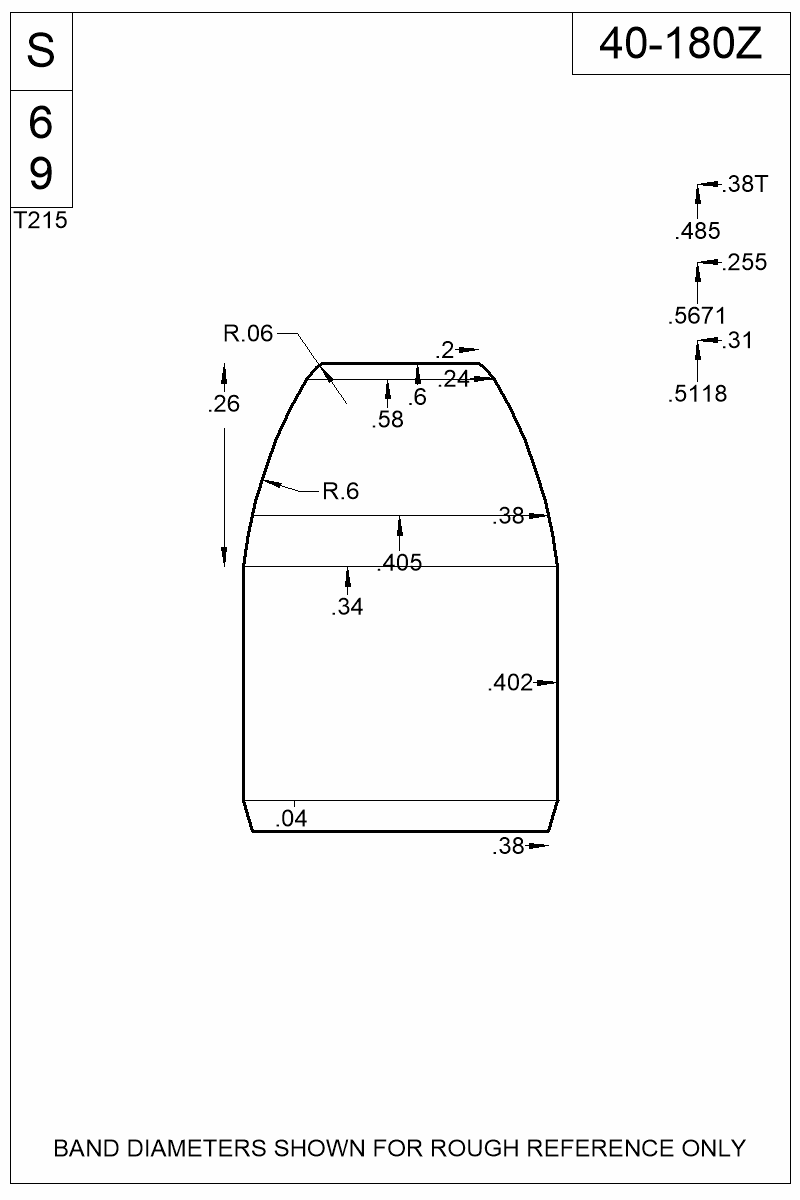

takin this one as reference : sure i get some of the numbers here, then some means mystery for me like those in the upper right . seems i even cannot identify with certainty where the AOL is among the numbers i see in the upper right .

i'm reading a .402 to.405 taper in the shape of this design!? .

also shapes looks more like a RNFP with the obvious round shape of the body before hitting the .250 meplat(same has my design) . there's also the R6 ; i have a .200 R6 ,on the draw here it's .260 .

not sure i read this correctly.

|

|

|

Reply With Quote

Reply With Quote