Let me see if I got this right.

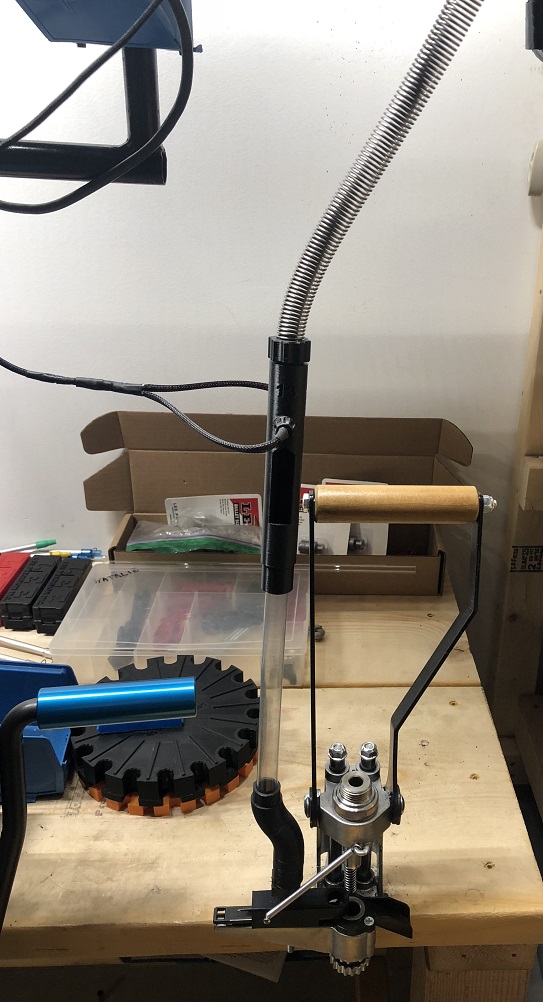

If I want to put the drop tube directly on top of the horandy drop tube adapter then I don't need an adapter below it. I'd just need to print the adapter to have the spring go directly to the drop tube. I had previously thought I wanted the drop tube as high as possible to have as much in the tube/spring before shutting off the motor. But I'm not sure that's going to be much of an issue as the collator will likely be faster than I can load or deprime, and it doesn't appear to really give me a ton of advantage.

|

|

|

Reply With Quote

Reply With Quote