So folks who are using the DAA dies, what solution are you using to secure the drop tube to the die? I don't have the brass weight so I wasn't sure if there is something I can print to use springs/o-rings/rubberbands. Thanks!

|

|

|

So folks who are using the DAA dies, what solution are you using to secure the drop tube to the die? I don't have the brass weight so I wasn't sure if there is something I can print to use springs/o-rings/rubberbands. Thanks!

Right the issue is there is nothing to put downward pressure on the top/inner part of the die and it doesn't drop back down nicely because of the tension being put on it due to the the drop tube and spring sitting on top of it pulling it slightly to the side. Basically the same reason why the 3d printed dies have the spots for the o-rings/rubberbands to pull down the inside portion of the die back down.

Awesome! Thanks!

I also broke the awesome 300bo brass plate. My pin on my motors are drilled higher which the hex slot was too low being a thinner plate. Thanks for all the work on these and the scad awesomeness.. Beefed it up and set it to higher so it's up a few more mm. Printing that now also. Man that was working great before it happened *cries*. Curious from your .223 brass vid looked like your pin was decently low. How high from the base floor is your pin? Mine is 10.5mm to the top of the pin from the base's floor. If I run into it again I'll shim my motor down a touch.

oh gotcha. I used the stl in the zip that was 9mm high just barely hit the pin and caused pressure and snapped the hex handle. I looked in the scad and saw the min of 8mm so just changed some in there, overkill probably... height of 13mm says cura.

Edited: hah, how about that. did a quick one from the current generator and it made it taller indeed.

Last edited by djinnpb; 11-18-2020 at 06:53 PM.

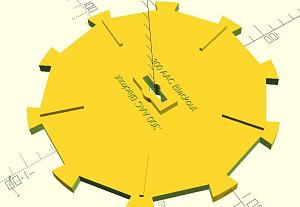

Just updated it to v1.1.5.

- All hex plates have been re generated with pin slot on angle instead of flat.

- Another minor reliability tweak to "Slide_Feed_Nose_Up_#11".

Promise I am done for now, until I get some feedback.

So I am cooking up a new idea inspired by my friend GWS. I won't say what it is yet, but it is a change to the main body, so will only benefit people who print new ones. But it should help improve reliability for certain situations. I bet he can probably guess what it is.

Ahh got it, thank youMy slide plates are 75mm wide. I did that to have more options for these weird kinds of plates. The originals were 50mm wide. I just measured and if I shaved 4mm off the riser length I could get it down to 50. You want me to give it a try?

OK, I just modified it. It's posted

Last edited by TylerR; 11-18-2020 at 08:56 PM.

______________________________________________

Growing old is mandatory, growing up is totally optional!

I did measure it compared to his original plate and the dimensions are right on. Let me know if it needs tweaking.

Edited:

I just tried to generate a 147.5mm plate using my new isLongRifleBullet = true param, and there are definitely issues. Perhaps as our resident SCAD guru you could resolve them. My technique with all the math is, how shall I say it, hack and slash.

Last edited by TylerR; 11-18-2020 at 09:31 PM.

Ok both plates are posted for anyone else who wants to take a crack at it. But you are going to have to wait for Ed to tweak the scad cause I aint doing it!

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |