OK so I got a modified version headed to the printer. I am going to be crazy and actually use supports. Did I happen to mention I hate using supports?

|

|

|

OK so I got a modified version headed to the printer. I am going to be crazy and actually use supports. Did I happen to mention I hate using supports?

Yup, that why I posted it......I like that print part you have....I didn't have that option.

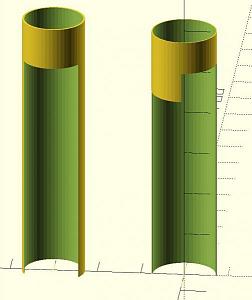

But the beveled tops really bug me.....they should have figured out that beveling edges just prevents a straight drop......especially with no support around the cases. Which is why I made these:

One is for .308 and one is for .223. You could make nice ones with the printer! What they do is guide the cases straight down to the slider using the SAME height setting for both calibers.....and that helps fix one of my biggest pet peeves with the APP. How hard it is to change calibers. That was my first goal.....make caliber changes easier.

The following short video shows how I use the ugly little tubes to help me quick change from one rifle to another. Maybe you can come up with a 3d printer-made solution that does the same thing. Now THAT would be cool!!!

As for finding the bolt I use a bigger nut!

Last edited by GWS; 10-18-2020 at 08:18 PM.

Hi guys. How about something like this? You have a central (inner) tube that has a slot to allow both .223 and .308 to slide out. Then you have an outer tube that you can rotate to allow a "window" for either the .233 or .308. This is just a rough concept drawing, but I think you get the idea. One tube with a "dial" indicator of which case to use.

Ed

______________________________________________

Growing old is mandatory, growing up is totally optional!

I am very intrigued. Would it be possible to replace the whole tube interface to where height adjustments were not required based on the caliber. Just insert the correct inner tube? Now that would be slick.

To clarify what I mean, building off Ed's idea. You have a universal tube that mounts to the press at a fixed height. Then just insert and twist an inner tube in to it and it sets the correct depth and everything else for that caliber.

Perhaps one inner tube could serve multiple calibers, like .223/.308 or 9mm/45acp, which if I am understanding you Ed that would be part of the concept. But ideally never having to reset the height of the base platform, which is the biggest pain.

Last edited by TylerR; 10-18-2020 at 10:22 PM.

Why else would I show those pictures!......I knows there gots to be a cleaner, better way......just have to get people thinking about it.I have faith......already stuff to mull over and investigate....thankyou, gentlemen!

That's the goal and while were at it, make it easy to change the incoming down tubes......since one tube doesn't fit all. that's why in the video I had to unscrew it and screw in the other bolt on the other side. Would prefer not to have to do that.

Back to the drawing board......and maybe even time to start thinking about a rifle case feeder to feed it.

Last edited by GWS; 10-18-2020 at 10:56 PM.

Woooohoooooo

Need a little more angle and I’m golden

Just posted a new version of the APP brass slide base that does not require modification to the original part. The best way to print is to orient with the tab side on the build plate like shown in the picture. Use supports from the build plate up only and change "support overhang angle" to 60.

Here is a short video showing how quickly it can be swapped.

Last edited by TylerR; 10-20-2020 at 11:45 AM.

This is too funny. I just downloaded your stash one more time last night to get your APP goodies. So what's one more time?Looks perfect to me.

I had to pull my little wire goodies to use the base for some other things. Does the same go for yours? Look forward to printing one out. Way nicer than mine! Thanks!

Mixed signals here.....in the video you just showed, you connected your piece to the part with the pinchers did you not? You trying to confuse my simple mind?Is the "claws" something else?

The base should work for most, but it may have problems with revolver brass with rims that stick out.

I printed one and it works great for .40S&W!, what I shoot most of. The biggest PIA was with the pincher adjustment....nothing to do with your print.

There is some cleanup, but that's to be expected with a print requiring supports. Good Job!

Last edited by GWS; 10-20-2020 at 06:39 PM.

Finally, getting back to printing... CR10-V2 with ABS using the cheapest heat-sock I could make... I'm an hour into the print, should be 15 hours total using a 1MMS nozzle. Expect an update tomorrow afternoon...

Thanks Tyler for the files, I've got a motor on hand and hopefully having a working loader by the weekend.

Lakehouse2012

Sent from my SM-A102U using Tapatalk

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |