Could be Don, it feels smooth enough though. I will check it out.

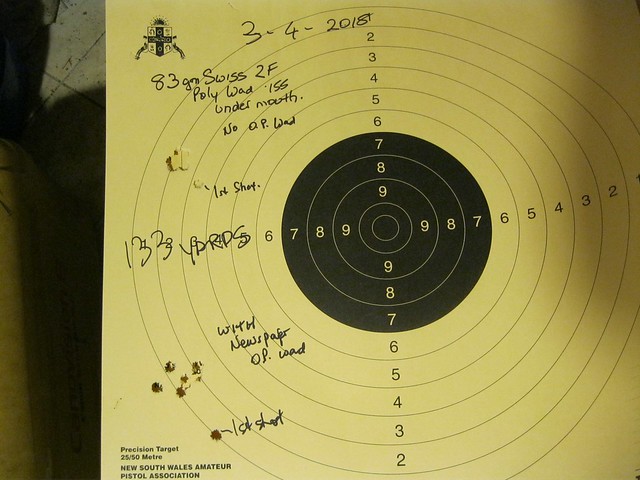

I was blaming the Wano as not having enough grunt to bump up the undersize boolit with just the .060 card behind it.

When it had the poly wad behind it I figured the poly was protecting the base and didnt need the bump up.

I will see what the extra thou makes when I get the sizer made.

My wife shoots F class with a 6.5 - 284 so I have a bunch of her old stainless barrels here. I have to fit and chamber a new one every couple of years.They are usefull for turning into things that need a ready made pilot hole.

When I get the thing grouping it will be interesting to put it over the chrony and see the difference between the Wano and the Swiss.

|

|

|

Reply With Quote

Reply With Quote