I am loading up cast LRN .45acp 230gr bullets and have a question.

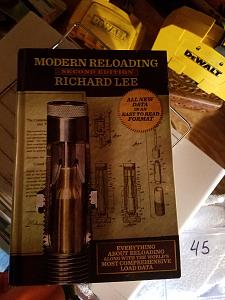

I am using the load data I found in modern reloading manual second edition

Powder HS-6 Start 7gr Max 8gr

I was using 7.1-7.2

stated min OAL to be 1.20

So when I used all this information the result was a case that looked odd to me. It looked like the bullet was seated too deep into the case even though it was loaded to the manuals specification.

Here are some pictures. Does it look add to you as well, would this be safe to shoot? could I seat less and be good? I usually seat my .45acp rounds to 1.25" using various other powders with good results.

|

|

|

Reply With Quote

Reply With Quote