This is how

I wired my temperature controller:

Items purchased from

http://auberins.com/

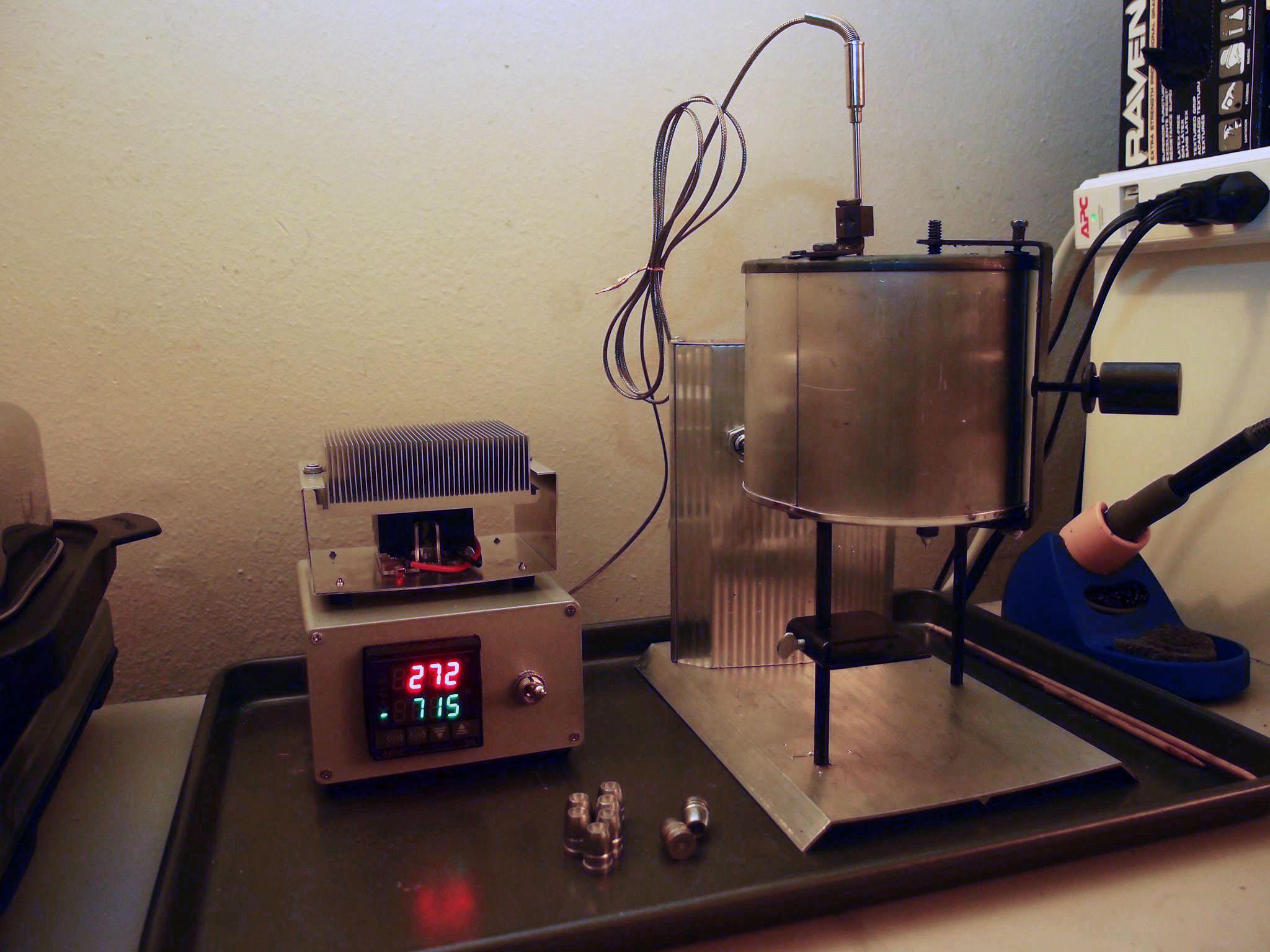

Universal 1/16 DIN PID Temperature Controller

http://auberins.com/index.php?main_p...products_id=90

25 amp SSR (solid state relay)

http://auberins.com/index.php?main_p...&products_id=9

Heat sink for SSR (will help maximize the life of the SSR)

http://auberins.com/index.php?main_p...products_id=45

K type thermocouple high temperature

http://auberins.com/index.php?main_p...products_id=22

Item purchased or supplied locally:

Crimp on wire connectors, spade type

Short heavy duty extension cord – my Lee pot has a 2 conductor plug and is not grounded, so the my wiring does not include a ground as nothing in the wiring needs it.

Small amount of extra wire for jumpers

Terminal wiring block. Mine has 2 rows of 4 screws. Available in the automotive section.

Procedure:

1) Mount terminal block to base

2) Cut extension cord in half. Strip wires and crimp in spade terminals.

3) Attach 2 modified cords to one side of terminal block in order from left to right---

a. Outlet black | outlet white | plug white | plug black

b. This is the inlet/outlet side of the terminal block, the other row is all for internal connections. The Outlet refers to the end of the cord you will plug the casting pot into.

4) Mount SSR to heat sink and mount this assembly to the base. Don't forget to put a dab of the white heatsink grease on the back of the SSR before you attach it.

5) Wire T1 of SSR to screw terminal across from Black Plug Wire

6) Wire L1 of SSR to screw terminal across from Black Outlet wire

7) Install a short jumper wire from screw terminal across from White Outlet Wire to screw terminal across from White plug Wire

8) Mount PID controller to base

9) Run a pair of wires from screws across from White Plug Wire and the Black Plug Wire to PID AC/DC input contacts 1 and 2 on my controller, polarity does NOT matter with AC power

10) Run a wire from PID SSR+ (contact #6) to SSR A1+

11) Run a wire from PID SSR- (contact #7) to SSR A2-

12) Connect the thermocouple to PID TC (contacts 9 and 10)

I wanted to add some pictures but haven't figured out how to do that.

Reply With Quote

Reply With Quote