This page at my Swedish Mauser website gets a very high visitor count consistantly. It concerns the 1895 Chilean Mauser conversions to 7.62x51 Nato. What has brought this page so much attention with Mauser collectors is the cut-a-way of the chamber showing the soldered insert. No less than John Wall, Mauser collector & researcher supreme routinely refer to this page.

http://dutchman.rebooty.com/1895Chile.html

I had purchased two of these 1895 Mausers from Century in one of their pallet sales for $65 each. Both were rather ratty but I wanted them for shop projects as mock up models and the like. Looking into the chamber one day I noticed this sliver ring at the end of the barrel and wondered what it be.. So, I removed the barrel and sure enough there was a silver ring around the chamber. Having a vertical milling machine at home makes jobs like this fun so I clamped it up in the mill and took a thin 3" x .062" thick cutter with side clearance teeth and sliced this puppy open. Imagine my surprise when this is what I found. Apparently nobody had made this discovery yet as there was nothing anywhere on the web or in any Mauser book about this. I felt like Columbus.

Over the years these photos have provoked a lot of discussion on the issue of 7.62x51 Nato in 1893 and 1895 Mauser actions. Many newbies refer to Samco Global's White Laboratory ~paper~ on the strength and safety of the general topic. IMO, its BS. These conversions were done as an expedient means of utilizing existing rifle inventories in a country short of pesos intended for 2nd line use. They were never intended to chamber and fire .308 Winchester ammunition.

One of the secondary discoveries isn't evident in these photos but involved an excess of copper fouling in the bore an inch or so in front of the chamber. The rifling in this area for about 2 inches was more heavily fouled with copper than the whole rest of the 29" long barrel. Why? I sat there in the shop and it finally dawned on me, something taught to me by the old Mexican blacksmith & welder in a Los Angeles rail shop decades ago.

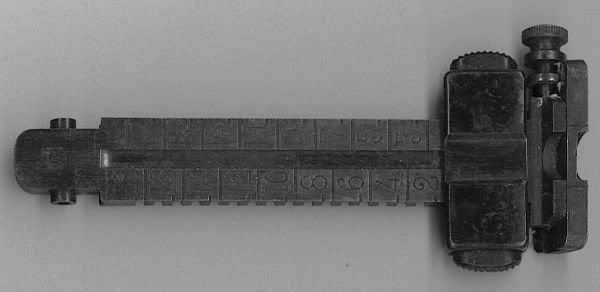

Heat causes steel to shrink. The place where the excessive copper fouling occured was directly underneath the rear sight base and extended about the exact length of the rear sight base. When the rear sight bases were re-attached and soldered in place this one was overheated to the point that the bore dimension shrunk enough to tear off copper from the bullet as it was swaged down zipping through the barrel. I wonder what that did to chamber pressure and accuracy?

Wasn't hard to figure where the solder went from gaps in the joint. Powder gases were hot enough to melt and vaporize the solder. My eyes see a silver bearing solder. I've done a lot of silver soldering with 99.9% pure silver, also a subject lesson from Pete Jimenez long ago.

Some things you can learn from a book. This isn't one of them.

Dutch

|

|

|

Reply With Quote

Reply With Quote