I'm going to GC and PC the boolits and try and run them 2000 plus fps if accuracy is there.

My plan is to use AC COWW with 2% pewter. I would like them alloy to be soft enough to mushroom p. I'm using a Lee 200g mold and run them out of a Marlin 336 and 7600 Remington.

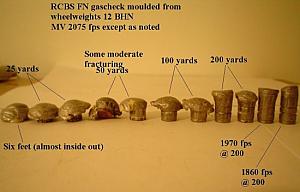

I found this pic yesterday. I believe it was ACCOWW around 2000fps.

My COWW are 13.4 BH and adding pewter will no doubt make it harder. This guy is running 12bh. He added 20% pure load to the mix and his boolit fragmented into pieces. How could I bring my BH Down without fragmenting? 50/50 with 6% pewter I'm guessing?

|

|

|

Reply With Quote

Reply With Quote